Have you ever needed to drill a huge hole in a piece of wood or metal but discovered that your ordinary drill bit wouldn’t cut it? The hole saw, a specialized cutting instrument built exclusively for drilling big-diameter holes, comes into play.

Can a hole saw be used on a drill press, the versatile power instrument valued by both woodworkers and metalworkers? The answer is yes, but there are a few crucial factors to consider.

In this post, we’ll go over the ins and outs of utilizing a hole saw on a drill press, including the advantages, disadvantages, and safety concerns. Whether you’re a seasoned DIYer or new to power tools, keep reading to learn about using a hole saw on a drill press.

What is a Hole Saw?

What is a Hole Saw?

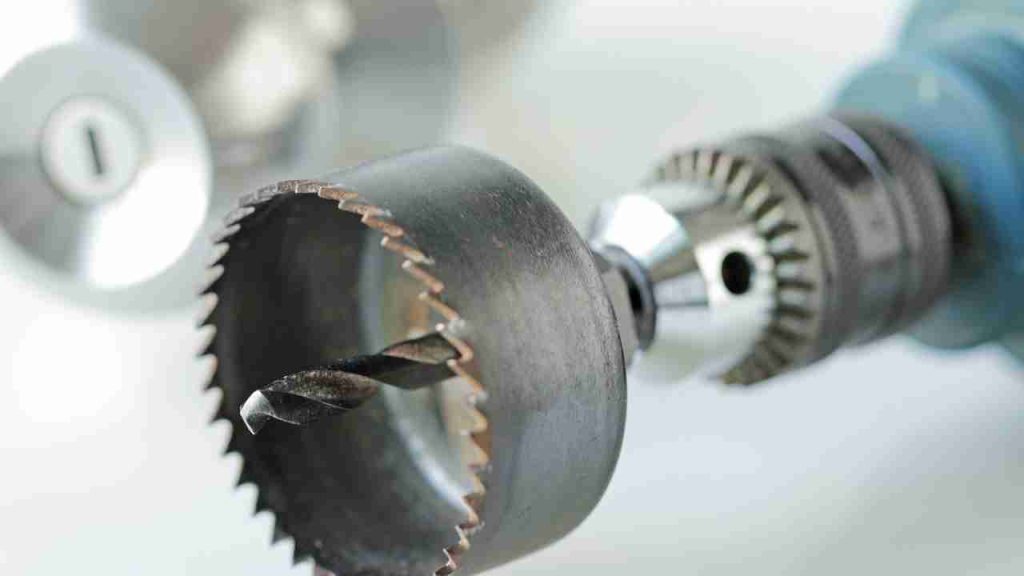

A hole saw is a specialized cutting instrument used to drill large-diameter holes in various materials such as wood, metal, and plastic. Unlike normal drill bits, which can only drill holes up to a particular size, hole saws can drill holes ranging from 1/4 inch to several inches in diameter.

A hole saw comprises a cylindrical arbor that fits into a drill chuck and has a saw blade attached to the end. The saw blade is commonly toothed, with teeth composed of hardened high-speed steel or carbide, and it rotates around the central arbor to cut through the material. Adjustable hole saws enable you to vary the diameter of the hole being cut by adding or deleting saw teeth.

Different types of hole saws:

Various hole saws are available, each tailored for a unique drilling use. Following are some of the most prevalent holes saw kinds and their applications:

- Standard Hole Saws: These are the most widely used hole saws, varying in diameter from 1/4 inch to several inches. They often make holes in wood, plastic, and soft metals.

- Carbide-Tipped Hole Saws: These hole saws are designed to drill holes in tougher materials including ceramic, concrete, and stone. They feature carbide teeth that are tougher and more durable than a regular hole saw teeth.

- Diamond Grit Hole Saws: Similar to carbide-tipped hole saws, these holes are meant to pierce even harder materials such as glass, tile, and granite. They feature diamond grit teeth that are exceedingly hard and can cut through even the most difficult materials.

- Adjustable hole saws enable you to change the size of the hole you’re cutting by adding or deleting saw teeth. They are excellent for drilling holes of various diameters and may be used on multiple materials.

- Specialty Hole Saws: Specialized hole saws are offered for various drilling applications. There are hole saws built specifically for cutting square or rectangular holes and hole saws developed specifically for cutting holes in thin materials such as sheet metal.

Can You Use a Hole Saw on a Drill Press?

Yes, a hole saw may be used on a drill press, and many woodworkers and metalworkers choose to do so. Combining a drill press with a hole saw delivers higher precision, stability, and control than a handheld drill.

The procedure of utilizing a hole saw on a drill press is fairly similar to that of using a standard drill bit. To avoid drilling too deeply, hold the workpiece to the drill press table using clamps or a vice, and then set the depth stop on the drill press.

Advantages:

- Increased Accuracy: A drill press gives more accuracy and precision when drilling holes with a hole saw. The drill press’s solid base and adjustable depth stop ensure that the hole is drilled to the proper depth and angle.

- Stability: While using a hole saw to drill, the workpiece might shift or move, causing the saw blade to bind or create an uneven hole. Utilizing a drill press with a hole saw helps to avoid this issue by firmly holding the workpiece in place and creating a steady drilling surface.

- Control: Unlike a portable drill, a drill press gives you more control over the speed and power of the drill. This simplifies drilling holes with a hole saw without injuring the material or the saw blade.

- Hole Saws are intended to drill bigger diameter holes than normal drill bits, and utilizing a drill press enables you to drill larger holes with better ease and accuracy.

Disadvantages:

- Cost: A drill press is a more costly instrument than a portable drill, so if you still need one, utilizing a hole saw on a drill press may be prohibitive.

- Restricted Mobility: Since a drill press is a stationary instrument, it is not movable and can only be used in one spot. This might be troublesome if you need to drill holes in many areas or materials too big to fit on the drill press table.

- Drill presses exist in various sizes, and certain versions may not be able to support greater-diameter hole saws. If you need to drill holes with particularly big diameters, purchase a larger and more costly drill press.

- Concerns for Safety: Using a hole saw on a drill press necessitates attention and care to prevent harm. Wear protective clothing to keep the saw blade from overheating or breaking, observe safety standards, and utilize the proper speed and force settings.

How to use a hole saw on a drill press?

- A certain set of actions must be followed to guarantee safe and precise drilling while using a hole saw on a drill press. Here’s how to use a hole saw on a drill press in detail:

- Choose the Appropriate Hole Saw: Pick a hole saw that is suitable for the material you will be drilling and the size of the hole required.

- Clamps or a vise should be used to secure the workpiece to the drill press table. Ascertain that the workpiece is firmly positioned and will not move during drilling.

- Mark the Center of the Hole: With a center punch, mark the center of the hole you want to drill. This will assist in guaranteeing that the saw blade is correctly aligned and the hole is drilled in the right spot.

- Insert the Hole Saw: Securely insert the hole saw into the drill press chuck. Check that the saw blade is centered and does not wobble or shake.

- Set the depth stop on the drill press to the right depth for the hole you will drill. This will save you from drilling too far into the workpiece and ruining it.

- Turn on the drill press and adjust the speed to the right setting for your drilling material. A slower speed is preferable for most materials to avoid overheating or damaging the saw blade.

- Begin drilling by slowly lowering the saw blade into the workpiece and guiding it with the drill press handles. While drilling, use light pressure and maintain the saw blade level straight. To prevent overheating or destroying the saw blade, drill gently and steadily.

- Turn off the drill press and gently remove the saw blade from the workpiece after you’ve completed drilling. To prevent harm, be sure you use protective gloves.

- Clear up any dirt or sawdust from the work area, then use a wire brush or compressed air to clean the saw blade.

Best practices and tips:

- Choose the Appropriate Hole Saw: Pick a hole saw that is suitable for the material you will be drilling and the size of the hole required. Using the incorrect hole saw might cause harm to the saw blade or the workpiece.

- Clamps or a vise should be used to secure the workpiece to the drill press table. This will keep the workpiece from shifting or sliding throughout the drilling process, which might cause the saw blade to bind or produce an irregular hole.

- Mark the Center of the Hole: With a center punch, mark the center of the hole you want to drill. This will assist in guaranteeing that the saw blade is correctly aligned and the hole is drilled in the right spot.

- Employ the Proper Speed: The speed at which you drill with a hole saw is determined by the material being drilled. Use the manufacturer’s instructions or a speed chart to establish the right speed setting for your drilling material.

- Use Little Pressure: When drilling with a hole saw, use mild pressure to avoid overheating or destroying the saw blade. Let the saw blade perform its job rather than forcing it through the material.

- Maintain the Saw Blade Cool: Use cutting fluid or lubrication to keep the saw blade cool and avoid overheating. The saw blade might deform or shatter if it becomes too heated.

- Remove Debris: Pause the drill press regularly to clean debris from the saw blade and the drilled hole. This will assist in keeping the saw blade cool and produce a clean, precise cut.

- Use Protective Gear: To avoid harm and protect yourself from dust and debris, wear protective gear such as safety glasses, gloves, and a dust mask.

- Inspect the Saw Blade Frequently: Examine the saw blade for indications of wear or damage regularly. If the saw blade gets dull or damaged, replace it immediately because utilizing a worn or damaged saw blade might harm or damage the workpiece.

Safety Considerations:

- Using a hole saw on a drill press may be a safe and efficient technique to drill big-diameter holes, but proper safety procedures must be taken to avoid injury or damage. These are some safety precautions to take while using a hole saw on a drill press:

- Use Protective Gear: To protect yourself from dust and debris, always wear protective gear such as safety glasses, gloves, and a dust mask.

- Read the following instructions: Carefully read the manufacturer’s instructions before operating the hole saw or drill press. Observe all safety precautions and standards.

- Employ the Proper Speed: Using the proper speed setting for drilled material might help keep the saw blade from overheating or breaking. See the manufacturer’s instructions or a speed chart to establish the proper speed setting.

- Use Low Pressure: Excessive pressure while drilling with a hole saw might cause the blade to overheat and shatter. Use little pressure and let the saw blade perform the job.

- Maintain the Saw Blade Cool: Use cutting fluid or lubrication to keep the saw blade cool and avoid overheating. The saw blade might deform or shatter if it becomes too heated.

- Remove Debris: Pause the drill press regularly to clean debris from the saw blade and the drilled hole. This will assist in keeping the saw blade cool and produce a clean, precise cut.

- Inspect the Saw Blade Frequently: Examine the saw blade for indications of wear or damage regularly. If the saw blade gets dull or damaged, replace it immediately because utilizing a worn or damaged saw blade might harm or damage the workpiece.

- Clamps or a vise should be used to secure the workpiece to the drill press table. This will keep the workpiece from shifting or sliding throughout the drilling process, which might cause the saw blade to bind or produce an irregular hole.

- Caution with Thin Materials: When drilling with a hole saw, thin materials such as sheet metal may easily be distorted or damaged. To prevent harming the material, proceed with care and use little pressure.

Frequently Asked Questions (FAQs)

1. Can I use a hole saw with a handheld drill instead of a drill press?

Yes, you can use a hole saw with a handheld drill. However, using a drill press provides more stability, control, and precision when drilling large-diameter holes. If you choose to use a handheld drill, make sure to secure the workpiece properly and follow safety precautions.

2. What materials can I cut using a hole saw?

Hole saws can cut through various materials, such as wood, plastic, metal, ceramic, concrete, stone, glass, and tile. The type of hole saw you use depends on the material you are cutting. Make sure to choose the appropriate hole saw for the specific material you are working with.

3. How do I choose the right hole saw for my project?

To choose the right hole saw, consider the material you will be cutting and the size of the hole you need to drill. Use standard hole saws for wood, plastic, and soft metals; carbide-tipped hole saws for ceramic, concrete, and stone; and diamond grit hole saws for glass, tile, and granite. Adjustable hole saws are suitable for drilling holes of various diameters in multiple materials.

4. How do I maintain my hole saw?

To maintain your hole saw, clean it after each use with a wire brush or compressed air to remove debris. Inspect the saw blade regularly for signs of wear or damage, and replace it if necessary. Lubricate the saw blade with cutting fluid to keep it cool and prevent overheating during use.

5. What safety precautions should I take when using a hole saw on a drill press?

When using a hole saw on a drill press, wear protective gear such as safety glasses, gloves, and a dust mask. Secure the workpiece with clamps or a vise, and follow the manufacturer’s instructions for proper speed and pressure settings. Use cutting fluid to keep the saw blade cool, and inspect the saw blade regularly for signs of wear or damage.

Final words:

Finally, drilling big-diameter holes in various materials using a hole saw on a drill press is a safe and efficient. You may make accurate and exact cuts every time by selecting the suitable hole saw, securing the workpiece, and following relevant safety procedures.

Combining a drill press with a hole saw delivers higher precision, stability, and control than a handheld drill. Nevertheless, there are some possible drawbacks and safety concerns, such as the expense of a drill press, restricted mobility, and the need to wear protective gear.

Combining a drill press with a hole saw delivers higher precision, stability, and control than a handheld drill. Nevertheless, there are some possible drawbacks and safety concerns, such as the expense of a drill press, restricted mobility, and the need to wear protective gear.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023