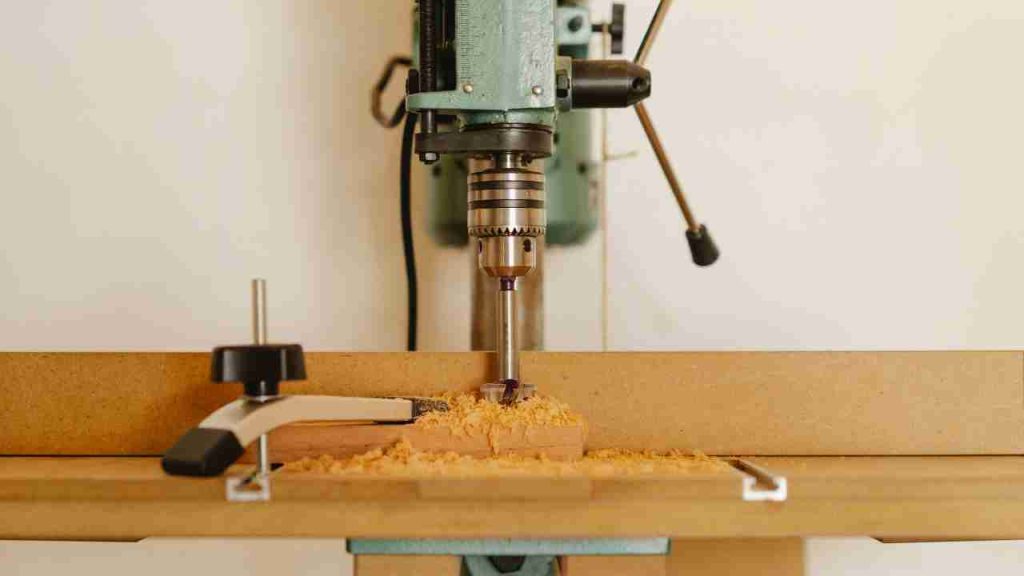

Any DIY enthusiast, hobbyist, woodworker, or professional metalworker understands the importance of a dependable drill press in their workshop. This adaptable piece of machinery has earned its deserved position as the foundation of several projects, from basic to complicated. Yet, despite its ubiquitous usage, one issue often stumps people: how deep can a drill press go?

You’re in for a treat today, my fellow workshop warriors! In this blog article, we’ll take a deep (pun intended) dive into the world of drill presses and learn about the elements that influence their drilling depth.

We’ll also provide some pointers and tactics to help you optimize the capabilities of your drill press and get the most bang for your money. So, put on your safety goggles and go to work!

4 Factors That Determine Drilling Depth:

4 Factors That Determine Drilling Depth:

1. Quill travel:

The vertical distance the quill (the portion of the drill press that holds the spindle and chuck) may move up and down is referred to as quill travel. This distance determines how deep your drill press can bore into a workpiece. The deeper the prospective hole, the greater the quill travel.

Differentiating quill travel from spindle travel: While both terms are related, spindle travel refers to the vertical distance the spindle can move, which typically equals quill travel. In other words, they are directly linked and essential for understanding your drill press’s capabilities.

2. Drill press swing:

A drill press swing is the distance from the center of the spindle to the column multiplied by two. Although the swing is often used to define the greatest width of the workpiece that can be worked on, drill presses with bigger swings frequently have longer quill travel, allowing for deeper drilling.

3. Drill bit length

Drill bits exist in a variety of lengths, and selecting the proper one may have a big impact on your drilling depth. Longer bits help you to drill deeper holes, but you must ensure that your drill press’s quill travel can support the extra length. Consider the sort of material you’re dealing with and the design of the drill bit when choosing one since these aspects will affect its performance and lifespan.

4. Material type and thickness:

The drilling depth is also affected by the material’s kind and thickness. To prevent harming your drill bit or workpiece, harder materials like metal or hardwood may need slower drilling rates and a more progressive approach.

Longer drill bits or numerous passes with various bit sizes may be required to obtain the necessary depth in thicker materials. Knowing how to deal with diverse materials is critical for optimizing your drill press’s capability and guaranteeing effective, accurate output.

Tips for Maximizing Drilling Depth:

1. Choosing the right drill press model

When choosing a drill press, consider whether a tabletop or floor-standing type is ideal for your requirements. Floor-standing variants often feature greater quill travel, allowing for deeper drilling, whilst tabletop models are smaller and more portable. While making a decision, consider your workplace, the kind of tasks you generally work on, and your budget.

2. Selecting the appropriate drill bits

Using drill bits appropriate for the material you are dealing with is critical. For example, high-speed steel (HSS) bits are suitable for a wide range of materials, whereas carbide-tipped or cobalt bits are ideal for harder materials such as stainless steel.

Drill bit kinds and uses: Drill bits come in various shapes and sizes, each with its own set of applications. For deep drilling, consider using a parabolic flute or a gun drill bit, designed to remove chips efficiently while reducing the risk of binding or overheating.

3. Proper workpiece support and clamping

Ensure deep drilling safety and accuracy: Maintaining accuracy and safety requires properly fastening your workpiece to the drill press table. Use clamps, vises, or other holding devices to keep your workpiece from sliding while drilling. Also, check that your drill press table is level and capable of supporting the weight of your workpiece.

4. Techniques for drilling deep holes

When drilling deep holes, beginning with a smaller pilot hole is typically beneficial. This guides your bigger drill bit, guaranteeing precision and lowering the possibility of wandering or binding. After the pilot hole is complete, change to the necessary bit size and drill the hole to the needed depth.

Safety Considerations for Deep Drilling:

1. The importance of proper protective gear

- Eye protection: Always use safety glasses or goggles to protect your eyes from flying debris and chips while using a drill press.

- Hearing protection: Extended exposure to power tool noise may cause hearing impairment. To reduce the danger, use earplugs or earmuffs.

- Use gloves and protective gear to protect your hands from sharp edges and splinters.

- Keep loose clothing, jewelry, and anything else from becoming trapped in the drill press when working.

2. Maintaining your drill press

Inspections and cleaning on a regular basis: Check your drill press for wear, damage, or loose components. Maintain a clean, debris-free drill press to maintain smooth operation and avoid accidents.

Lubrication and alignment checks: Lubricate moving components according to the manufacturer’s recommendations and inspect for misalignments that might compromise drilling accuracy or cause equipment damage.

3. Recognizing and preventing overheating

Overheating symptoms include reduced drill bit speed, increased friction, and smoke. This might signal that your bit is overheating and needs to be repaired or replaced.

Cooling procedures and breaks: Allow your drill bit to cool down regularly during deep drilling to avoid overheating. Use cutting fluids or lubricants as required to prevent friction and heat buildup.

4. Operating at the correct speed

Various materials and bit sizes need different drilling rates to get the best results and avoid damage. Use manufacturer specifications or a drilling speed table to find the right speed for your job. Harder materials often need slower speeds, while softer materials can withstand greater speeds.

Excessive force during drilling might result in bit breakage, overheating, or damage to your workpiece. Instead, let the drill bit to do the job and provide steady, mild pressure throughout the drilling operation.

Frequently Asked Questions (FAQs)

1. What is the average drilling depth of a drill press?

The average drilling depth of a drill press varies depending on the quill travel, drill press swing, and drill bit length. Most drill presses have a quill travel of 2 to 6 inches, which determines the drilling depth.

2. Can I drill deeper holes with longer drill bits?

Yes, using longer drill bits can help you drill deeper holes. However, you must ensure that your drill press’s quill travel can support the extra length, and the drill bit is appropriate for the material you are working with.

3. How do I choose the right drill bit for my drill press?

Choose a drill bit based on the material you are working with and the required hole depth. High-speed steel (HSS) bits are suitable for various materials, while carbide-tipped or cobalt bits are ideal for harder materials like stainless steel. For deep drilling, consider using a parabolic flute or a gun drill bit.

4. What is the difference between quill travel and spindle travel?

Quill travel refers to the vertical distance the quill can move up and down, while spindle travel refers to the vertical distance the spindle can move. They are directly linked and essential for understanding your drill press’s capabilities, with spindle travel typically equaling quill travel.

5. How can I prevent overheating when drilling deep holes?

To prevent overheating, allow your drill bit to cool down regularly during deep drilling, and use cutting fluids or lubricants as required to reduce friction and heat buildup. Also, avoid applying excessive force during drilling, as it can result in overheating and damage to the bit or workpiece.

6. Can I use a benchtop drill press for deep drilling?

You can use a benchtop drill press for deep drilling, but floor-standing drill presses generally offer greater quill travel, allowing for deeper drilling. Consider your workspace, the type of projects you typically work on, and your budget when choosing between a benchtop and a floor-standing drill press.

Final words:

We’ve gotten down to the nitty-gritty of what influences a drill press’s drilling depth, and we hope you found it useful. Knowing the elements that influence drilling depth, such as quill travel, drill press swing, drill bit length, and material type, is critical for getting the most out of your dependable workshop buddy.

Following the advice and strategies we’ve discussed for increasing drilling depth, such as selecting the correct drill press type, selecting the suitable drill bits, and employing adequate workpiece support, is critical in addition to knowing these elements.

And, of course, never forget the importance of safety when working with power tools. Following the safety considerations outlined will keep you and your equipment in tip-top shape for years.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023