The drill bit’s rotational speed is crucial when utilizing a drill press. This speed, expressed in revolutions per minute (RPM), may have a big effect on the precision and quality of the drilled hole and the drill bit’s life.

The drill press speed may be adjusted to work best for the material being drilled and the size and kind of drill bit being used. This enables the user to fine-tune the tool to the job at hand. This is crucial when dealing with various materials since some call for a slower drill press speed to minimize overheating and drill bit damage.

How drill press speed is measured?

The rotating speed of the drill bit as it is spinning is referred to as the “drill press speed.” According to the particular work, it is generally measured in revolutions per minute (RPM) and may vary from a few hundred RPM to several thousand RPM. The drill press speed may vary depending on some variables, including:

- Size and type of the drill bit: Drill bit size and type may significantly influence the ideal drill press speed. To avoid overheating and wear, larger drill bits and those made of more rigid materials can need a slower drill press speed.

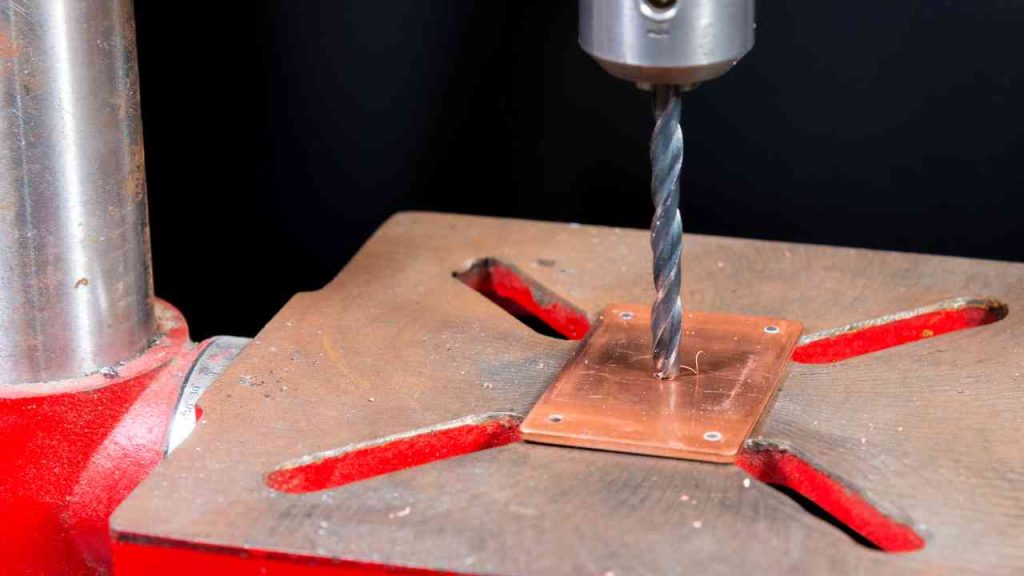

- Material being drilled: Drilling material might also influence the ideal drill press speed. A slower drill press speed may be necessary to avoid the drill bit overheating and breaking when drilling harder materials like steel or titanium. Faster drill press speeds may be suitable for softer materials like wood or plastic.

- Type of drill press: The possible drill press speeds may vary depending on the kind of drill press. Some drill presses may only have a small selection of speeds, especially those with mechanical controls. Other models, including those with electronic controls, could provide a more fantastic range of readily adjustable speeds.

Users may choose the ideal speed for the particular job by being aware of the variables that determine drill press speed. By doing so, they can ensure that the drill press is working at its best and delivering the greatest results.

How to slow down drill press speed? 4 Steps to Follow

When dealing with tougher materials, drilling precise holes, or increasing the life of the drill bit, slowing down the drill press speed might be advantageous. The following methods may be used to reduce the drill press’s speed:

- Determine the optimal speed: The first step in reducing the drill press’s speed is establishing the ideal speed for the given work. The size and kind will influence this and the material being drilled as well as the particular drill press being utilized. Use the manufacturer’s instructions or a speed chart to determine the suggested speed for a given job.

- Adjust the controls: The drill press’s settings must be modified to achieve the ideal speed once it has been established. This may include changing a dial on an electronic drill press, transferring the belt to a new pulley on a belt or pulley system, or altering the settings following a speed chart, depending on the kind of drill press.

- Test the speed: It’s crucial to check the drill press speed after setting the controls to ensure it’s set properly. To achieve this, turn on the drill press and measure the RPM using a tachometer or another tool. If the speed is off, change the settings as necessary to get the required speed.

- Use proper technique: After the drill press speed has been reduced, it is crucial to make the most of the slower pace by using the proper technique. This may include utilizing a lubricant, chewing more slowly, and using steady, even pressure to prevent overheating or harming the drill bit.

How are the speeds of the drill press adjust?

The drill press speed may be changed using various mechanical and electrical techniques. Here are a few typical techniques for changing drill press speed:

- Belt or pulley system: Many drill presses use a belt or pulley system to alter the speed of the drill press. A belt connects a group of pulleys of various diameters to form this system. The user may alter the speed by shifting the belt to a different pulley, which changes the pulleys’ ratio and alters the drill press’s speed.

- Speed dial: A speed dial is a feature that certain drill presses offer that enables the user to quickly change the drill press speed by rotating a knob or dial. This technique may provide a wide variety of readily adjustable speeds and is often encountered on computerized drill presses.

- Speed chart: Some drill presses, especially those with mechanical controls, could come with a speed chart that specifies the ideal speeds for various drill bit sizes and kinds. The user may modify the belt or pulley system to vary the speed by consulting the chart.

What are the 2 types of speed controls used in a drill press?

Mechanical controls and electrical controls are the two basic speed controls used in drill presses.

- Mechanical controls: A belt or pulley system is used by drill presses with mechanical controls to change the speed. A belt connects a group of pulleys of various diameters to form this system. The user may alter the speed by shifting the belt to a different pulley, which changes the pulleys’ ratio and alters the drill press’s speed. The recommended speeds for various drill bit sizes and kinds are listed on a speed chart with certain drill machines with mechanical controls.

- Electronic controls: Drill presses with electronic controls often contain a speed dial or another control that enables the user to quickly change the speed by turning a knob or dial. Because it enables the user to adjust the speed across a greater range precisely, this approach is often more practical and accurate than the mechanical control method. More recently, high-end drill presses often include electronic controls.

Benefits:

The ability to reduce the drill press’s speed has various advantages. It can, first and foremost, improve control and accuracy. It is simpler to keep constant pressure on the drill bit when the drill press operates at a reduced speed, which might lead to a smoother, more precise hole.

A slower drill press speed may also prolong the life of the drill bit by reducing tool wear and tear. Last but not least, lowering the drill press speed might make it safer since it lowers the possibility of the drill bit sliding or breaking. The ability to change the drill press speed is a crucial feature that may enhance the output quality and provide a secure working environment.

4 Tips for using a slower drill press speed:

When dealing with more rigid materials, drilling precise holes, or prolonging the life of the drill bit, using a slower drill press speed might be advantageous. Here are some pointers for maximizing a slower drill press speed:

- Use lubrication: Lubrication is essential to prevent heat buildup and drill bit wear while drilling more slowly. Depending on the material being drilled, this may take the form of cutting oil or a water-based lubricant.

- Take smaller bites: It’s typically a good idea to take smaller bites while drilling slowly rather than attempting to remove a lot of material at once. The drill bit’s lifespan may be increased and overheating may be avoided.

- Use a steady, even pressure: Drilling at a slower pace while applying steady, even pressure might help you maintain control and accuracy. Avoid using excessive pressure since doing so might lead to the drill bit binding or breaking.

- Follow the manufacturer’s recommendations: This will guarantee that the drill press is utilized appropriately and safely by adhering to the manufacturer’s recommendations for drill press speed. Remember to modify the speed following the particular job at hand and the material being drilled.

Frequently Asked Questions (FAQs)

1. What is the ideal drill press speed for different materials?

The ideal drill press speed varies depending on the material being drilled and the drill bit size and type. Generally, harder materials like steel require slower speeds, while softer materials like wood can be drilled at higher speeds. Consult the manufacturer’s instructions or a speed chart for specific recommendations.

2. Can I damage my drill press by using the wrong speed?

Using the wrong speed can cause excessive heat, wear, and tear on the drill bit, which may lead to damage or reduce its lifespan. It’s essential to use the correct speed for the material and drill bit to ensure the best performance and prevent damage to the drill press or drill bit.

3. How do I know if my drill press speed is too slow or too fast?

If the drill bit is overheating or producing excessive smoke, the speed may be too high. On the other hand, if the drill press is struggling to cut through the material or taking an unusually long time, the speed may be too slow. Adjust the speed accordingly to achieve optimal performance.

4. Can I change the speed of my drill press while it’s running?

It’s not recommended to change the drill press speed while it’s running, as it can be dangerous and may cause damage to the drill press or the drill bit. Always turn off the drill press and disconnect it from the power source before making any adjustments to the speed.

5. What is the difference between variable speed and fixed speed drill presses?

Variable speed drill presses allow the user to adjust the speed according to the material and drill bit being used, providing greater versatility and control. Fixed speed drill presses operate at a single speed, which may be suitable for specific tasks but may not be ideal for all materials and drill bit sizes.

Final Word

Some advantages of using a slower drill press speed include better control and accuracy, longer tool life, and risk-free operating. Use lubricant, take smaller bites, and apply steady, even pressure to make the most of a slower drill press speed. Additionally, it’s crucial to adhere to the drill press manufacturer’s speed guidelines and modify the speed to the particular work at hand.

Changing the drill press speed is a crucial feature that may enhance the output quality and provide a secure working environment. We advise readers to experiment with various drill press settings to determine which speed is ideal for their requirements and to always adhere to the correct safety precautions while operating a drill press.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023