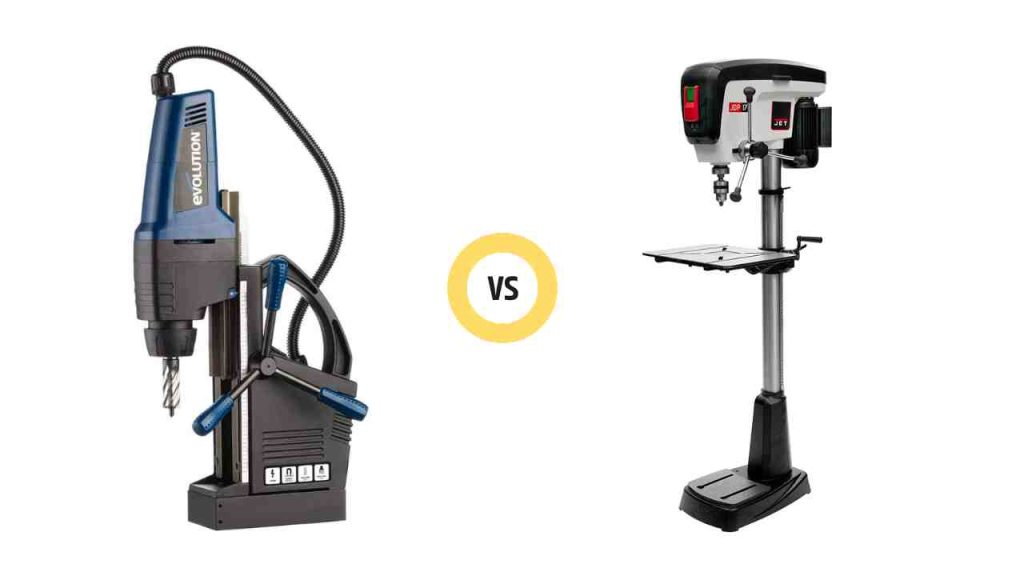

Mag Drills and Drill Presses are two typical solutions for drilling precise holes in metal surfaces. Both are power tools for drilling activities but have distinct characteristics, benefits, and drawbacks. Selecting the correct tool for the task may make or break the success of your endeavor.

We will compare and contrast Magnetic Drills and Drill Presses in this blog article to help you make an educated choice about which equipment is the best match for your requirements. This essay will give essential insights into the capabilities and limits of each instrument, whether you are a professional metalworker or a DIY hobbyist. Therefore, let’s dig in and learn about Mag Drills and Drill Presses!

Comparison chart between Magnetic Drill and Drill Press:

| Feature | Mag Drill | Drill Press |

| Design | Portable and lightweight | Stationary and heavy |

| Power source | Corded or cordless | Corded |

| Chuck type | Quick-change chuck or magnetic base | Standard keyed chuck |

| Magnetic base | Yes, used to secure the drill to the surface | Not applicable |

| Hole depth | Limited by the size of the magnetic base | Can drill deeper holes |

| Precision | High precision due to the magnetic base | Lower precision due to the drill press movement |

| User-friendliness | Easy to set up and use | Requires some experience to operate |

| Safety features | Automatic shut-off in case of power failure | Guard and safety switch for operator protection |

| Cost | Expensive compared to drill press | Affordable |

| Applications | Ideal for metalworking and construction | Suitable for woodworking and metalworking |

| Portability | Easy to move around the job site | Not easily portable |

| Speed variability | Variable speed available on some models | Multiple speed options available |

| Noise level | Relatively quiet | Noisy operation |

5 Major differences between Mag Drills and Drill Presses:

1. Design and Operation:

The design and functioning of Mag Drills and Drill Presses are unlike. Mag Drills have a magnetic base that sticks to metal, giving a solid surface upon which to drill. Yet, drill presses are stationary equipment that can make holes in a wide range of materials with the help of a spinning drill bit.

2. Performance:

The performance of Mag Drills and Drill Presses is distinct from one another. Mag Drills are the best option for drilling holes in metal because of their stable and precise magnetic foundation. Its engine is so strong that it can cut through rigid materials. Yet, drill presses are multipurpose tools that can drill straight holes and conduct countersinking and tapping.

3. Price:

Mag Drills and Drill Presses have different pricing points. Due to their sophisticated construction and high-end features, Mag Drills are often more costly than Drill Presses. The cost, however, may change depending on the tool’s make, model, and other specifications.

4. User-friendliness:

Mag Drills and Drill Presses are both simple to use once set up. Drill presses are ideal for novice users with their straightforward design and simple adjustment options. Mag Drills, on the other hand, have a unique design and set of features that may need more experience and training to use well.

5. Safety:

Mag Drills and Drill Presses include safety mechanisms to protect users from accidents. Drill Presses contain guards and safety switches to protect the operator from the whirling drill bit, while Mag Drills have a magnetic base that helps avoid slips and accidents. Due to their magnetic base and specific construction, Mag Drills may need particular vigilance during setup and operation.

Magnetic Drills:

Mag Drills, or magnetic drills, are specialized power tools that produce holes in metal surfaces with extreme accuracy and precision. These drills cling to a metal surface using a strong magnetic, allowing for steady drilling without clamps or vises.

As a result, they are great for drilling holes in massive metal surfaces such as beams, pipelines, and other structural components, where conventional drills may need to be more effective.

Components and features:

- Magnetic base: A unique characteristic of Mag Drills that allows them to attach to metal surfaces and provide stability during drilling.

- Drill chuck: This component holds the drill bit, a quick-change chuck, or a magnetic base that firmly retains several drill bit sizes.

- Motor: The motor generates the required power to move the drill bit through the metal surface.

- Variable speed control: Several Mag Drills include variable speed control, allowing users to alter the speed to fit the task needs.

- Depth stop: The depth stop controls the hole depth as it is drilled and may be changed to guarantee correct and consistent depth.

- Cooling system: The integrated cooling system sprays coolant on the drill bit to minimize overheating and reduce wear and tear on the bit and material being drilled.

- Power cable: Mag Drills come in corded and cordless varieties and are powered by a power cord that links the instrument to an electrical outlet.

- Control panel: The control panel has switches and dials for managing the Mag Drill’s operation, such as an on/off switch, speed control dial, depth stop, and coolant system control.

Advantages:

- Ensures precise and accurate drilling by providing a sturdy platform for drilling on metal surfaces.

- Allows for the fast and straightforward exchange of various drill bit sizes, enhancing efficiency and convenience.

- A powerful motor capable of drilling through thick and heavy materials.

- Variable speed control enables the user to tailor the speed to work at hand.

- Built-in cooling system that reduces overheating and extends drill bit life.

- Compact and lightweight design for greater mobility and adaptability.

- It may be utilized in small locations and at unusual angles where a standard drill press cannot fit.

- It requires little setup and is simple, making it a useful solution for DIY enthusiasts and pros.

Disadvantages:

- The magnetic base may not attach to certain metal surfaces, limiting its usage.

- Corded variants need electricity, which may not be available in certain settings.

Similarities:

- Drill presses and magnetic drills (often called “mag drills”) are helpful for precise, consistent drilling in a wide range of materials.

- Drill Presses and Mag Drills may be changed to modify the depth of the drilled hole.

- These tools may have multiple drill bit sizes to accommodate diverse hole diameters.

- Mag Drills and Drill Presses contain safety systems to keep the user safe.

- These tools offer variable speed control, which enables you to vary the speed of the drill bit to match the project’s needs.

- Mag Drills and Drill Presses require electricity to run their motors, and both are available in corded and cordless types.

Which one will be best for users? and why?

The selection between Mag Drills and Drill Presses is decided by the user’s particular needs and the work to do. A Mag Drill is the appropriate alternative if the user usually drills holes in metal surfaces and wants a portable device for precise and accurate drilling. A Drill Press is the right solution if the customer needs a versatile instrument that can execute a wide range of drilling operations and requires stability and precision for more precise drilling.

Frequently Asked Questions (FAQs)

1. Can I use a Mag Drill for woodworking?

While Mag Drills are primarily designed for metalworking, they can be used for woodworking if the magnetic base can be secured to a suitable metal surface. However, a Drill Press is generally a better option for woodworking due to its versatility and ability to handle various materials.

2. Can I use a Drill Press for metalworking?

Yes, Drill Presses can be used for metalworking as well as woodworking. However, Mag Drills are specifically designed for drilling precise holes in metal surfaces, so they may provide better results for metalworking tasks.

3. Are Mag Drills safe for beginners?

Mag Drills are relatively easy to set up and use, but they do require some experience and training to operate safely and effectively. Beginners should familiarize themselves with the tool’s features and follow the manufacturer’s instructions carefully to ensure safe operation.

4. How do I maintain my Mag Drill or Drill Press?

Regular maintenance is essential for both Mag Drills and Drill Presses. This includes cleaning the tool, lubricating moving parts, checking for wear and tear, and replacing damaged or worn components as needed. Always follow the manufacturer’s maintenance guidelines for your specific tool.

5. Are cordless Mag Drills as effective as corded ones?

Cordless Mag Drills offer the advantage of portability and can be used in areas without access to electricity. However, their performance may be limited by battery life and may not be as powerful as corded models. Consider your specific needs and work environment when choosing between corded and cordless Mag Drills.

6. What factors should I consider when choosing between a Mag Drill and a Drill Press?

When deciding between a Mag Drill and a Drill Press, consider factors such as the type of work you do (metalworking vs. woodworking), the need for portability, precision requirements, budget, and your level of experience with the tools. Assess your needs and choose the tool that best fits your specific requirements.

Final Words:

Mag Drills vs. Drill Presses are a tie. Both tools have merits and downsides, and the user’s needs and tasks will decide which one they select. Mag Drills are fantastic for users who work with metal surfaces and require precise and accurate drilling. At the same time, Drill Presses are suitable for users who need flexibility and stability for a larger range of drilling activities.

Follow the manufacturer’s guidelines and keep yourself and others safe when using these things. Customers may select the proper instrument by recognizing the distinctions between Mag Drills and Drill Presses and evaluating criteria like performance, cost, user-friendliness, and safety. Choose wisely, with security as your priority!

Mag Drills are great for users who work with metal surfaces and need precise and accurate drilling, whereas Drill Presses are good for users who need adaptability and stability for a broader variety of drilling tasks.

Follow the manufacturer’s directions and keep yourself and others safe while using these items. Users may pick the right instrument by knowing the differences between Mag Drills and Drill Presses and considering variables like performance, pricing, user-friendliness, and safety.

Follow the manufacturer’s directions and keep yourself and others safe while using these items. Users may pick the right instrument by knowing the differences between Mag Drills and Drill Presses and considering variables like performance, pricing, user-friendliness, and safety.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023