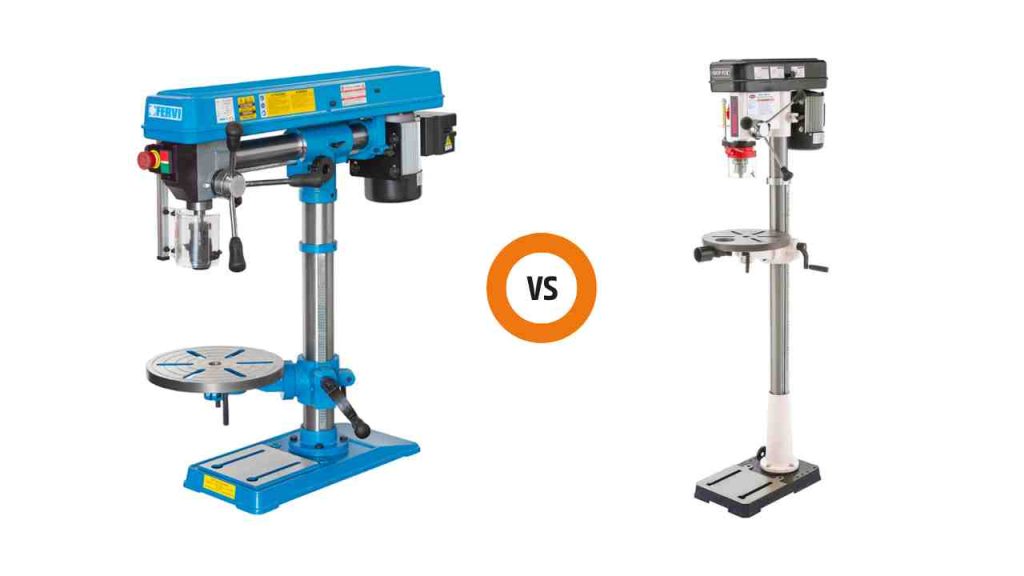

Regarding drill presses, there are two varieties to choose from Radial and Oscillating. Although both kinds are intended to drill accurate holes in various materials, they function differently and have distinct advantages and disadvantages.

Your requirements and tastes as a woodworker, metalworker, or DIY enthusiast will determine whether you choose a radial or oscillating drill press. Thus, whether you want to update your workshop or are just getting started, weigh the benefits and drawbacks of each kind before making a final selection.

Comparison chart:

| Feature | Radial Drill Press | Oscillating Drill Press |

| Movement | Arm can be adjusted to drill at different angles and positions | Quill moves up and down in a straight line |

| Chuck size | Larger chuck sizes, typically ranging from 1/2 inch to 5/8 inch | Smaller chuck sizes, typically ranging from 1/4 inch to 1/2 inch |

| Power | More powerful motors, typically ranging from 1/2 to 3/4 horsepower | Less powerful motors, typically ranging from 1/4 to 1/2 horsepower |

| Speed | Variable speed control, typically ranging from 500 to 3000 RPM | Variable speed control, typically ranging from 250 to 3000 RPM |

| Capacity | Able to drill larger materials and handle heavy-duty projects | Better suited for smaller materials and more delicate projects |

| Flexibility | More flexible and precise, able to drill at awkward angles and positions | More consistent and accurate, better suited for drilling straight holes |

| Price | Generally more expensive than oscillating drill presses | More affordable option for those who don’t need the extra power or flexibility |

5 major differences between radial and oscillating drill presses:

- Movement: The major distinction between radial and oscillating drill presses is their movement. Radial drill presses feature a moveable arm that may be adjusted to drill holes at various angles and places, while oscillating drill presses have a straight-line moving quill.

- Size and capacity: Radial drill presses are bigger and more powerful than oscillating ones, making them ideal for drilling larger materials or working on heavy-duty tasks. Oscillating drill presses are generally smaller and more compact, making them simpler to store and carry.

- Flexibility: Because of its adjustable arm, radial drill presses provide more flexibility and accuracy when dealing with bigger materials or drilling at odd angles. Since its quill enables more constant and precise drilling, oscillating drill presses are better suitable for smaller materials or more delicate jobs.

- Cost: Because of their bigger size, more power, and better flexibility, radial drill presses are often more costly than oscillating drill presses. Oscillating drill presses are a less expensive solution for people who want something other than a radial drill press’s additional power or flexibility.

- Maintenance: Both drill presses need regular maintenance to maintain correct operation and extend their lifetime. Radial drill presses, however, are more complicated and need more regular maintenance than oscillating drill presses, which are simpler and easier to operate.

Radial drill press:

Radial drill press:

The radial drill press is a flexible and strong piece of equipment for drilling holes at varying angles and places. Its flexible arm may be modified to fit the workpiece’s size and form, making it an excellent option for heavy-duty drilling jobs.

Major Features:

- Adjustable arm for drilling at various angles and places

- Huge chuck size (usually 1/2 inch to 5/8 inch)

- A powerful motor, ranging from 1/2 to 3/4 horsepower.

- Variable speed control, with a usual range of 500 to 3000 RPM

- High drilling capacity for heavier materials and heavy-duty applications

Advantages:

- Increases flexibility and accuracy while drilling at unusual angles and situations.

- Suitable for heavier materials and tasks.

- May be utilized for various drilling activities ranging from woodworking to metallurgy.

Disadvantage:

- More complicated and needs more regular maintenance than simpler drill presses.

What is a Radial drill press good for?

A radial drill press is useful for drilling huge materials, heavy-duty projects, drilling at various angles, precision drilling, and various other drilling activities.

What operations can be performed on a Radial drill press?

With specialized attachments, a radial arm drill press may execute drilling, countersinking, reaming, tapping, boring, and sanding/polishing operations

Oscillating drill press:

The Oscillating drill press is a tiny and economical equipment that enables constant and precise drilling for small materials or sensitive jobs. Its quill travels in a straight line up and down, making it perfect for drilling straight holes.

What does an oscillating drill press do?

An oscillating drill press that drills holes in various materials use a quill that goes up and down in a straight line. The oscillating quill delivers steady and precise drilling, making it excellent for drilling straight holes in tiny materials or delicate applications.

An oscillating drill press may also be used with appropriate sanding, polishing, mortising, and drilling accessories. The quill’s oscillating action may also assist in keeping the drill bit from overheating or becoming stuck, which is particularly critical when drilling tougher materials.

Major Features:

- A quill that goes up and down in a straight line.

- Small chuck size (usually 1/4 inch to 1/2 inch)

- a less powerful motor, often ranging from 1/4 to 1/2 horsepower.

- Variable speed control with a typical range of 250 to 3000 RPM

- Small size for ease of storage and transportation

Advantages:

- Consistent and precise drilling for smaller materials or more sensitive jobs.

- A less expensive choice than bigger, more complicated drill presses.

- Less regular maintenance is required, and it is often simpler to maintain than radial drill presses.

Disadvantage:

- Radial drill presses are less suitable for heavy-duty operations or drilling heavier materials.

Similarities:

- Precision: Both radial and oscillating drill presses are intended to deliver precision drilling for a wide range of materials, providing consistent and accurate drilling.

- Variable speed control: Variable speed control is available on both kinds of drill presses, enabling users to vary the speed of the drill bit to fit the material being drilled.

- Versatility: Although radial drill presses are better suited to bigger materials and heavy-duty projects, and oscillating drill presses are more suited to smaller materials and more delicate projects, both kinds of drill presses may be utilized for a variety of drilling operations.

- Depth stops: Several radial and oscillating drill presses include depth stops that enable you to adjust the depth of your hole, assuring constant and precise drilling.

- Simplicity of use: Both kinds of drill presses are simple and may be used by DIY enthusiasts, woodworkers, and metalworkers.

Which is better Radial or Oscillating drill press?

Which drill press is best, radial or oscillating, is ultimately determined by your unique demands and preferences. Both kinds of drill presses have distinct advantages and disadvantages, and the best selection for you will depend on the projects you’ll be working on and the materials you’ll be drilling.

A radial drill press with a moveable arm may be a preferable alternative for drilling heavier materials or heavy-duty jobs. When drilling at odd angles and locations, the radial drill press is more powerful, bigger, and more flexible.

If you’re dealing with smaller materials or more delicate tasks, an oscillating drill press with constant and precise drilling may be a better option. An oscillating drill press is generally less expensive, simpler to maintain, and more compact than a radial drill press.

Frequently Asked Questions (FAQs)

1. Can I use a radial drill press for small and delicate projects?

Yes, you can use a radial drill press for small and delicate projects, but it might not be the best choice due to its larger size and power. An oscillating drill press is better suited for smaller materials and more delicate tasks, providing consistent and precise drilling.

2. Can an oscillating drill press handle heavy-duty projects and larger materials?

An oscillating drill press is not the best choice for heavy-duty projects and larger materials due to its smaller size and less powerful motor. A radial drill press is more suitable for such tasks, as it has a more powerful motor and a larger drilling capacity.

3. Is it possible to convert a radial drill press to an oscillating drill press, or vice versa?

No, it is not possible to convert a radial drill press into an oscillating drill press or vice versa. These are two distinct types of drill presses with different designs and functionalities. It is essential to choose the right drill press based on your needs and requirements.

4. How do I decide which drill press is right for my workshop?

To decide which drill press is right for your workshop, consider the types of projects you’ll be working on and the materials you’ll be drilling. If you need flexibility and the ability to drill at various angles and positions, a radial drill press might be the better choice. If you work with smaller materials and require consistent and precise drilling, an oscillating drill press would be more suitable.

5. Can I use both wood and metal materials with a radial or oscillating drill press?

Yes, both radial and oscillating drill presses can be used for drilling various materials, including wood and metal. However, it is essential to use the appropriate drill bits and adjust the speed settings according to the material being drilled to ensure optimal performance and prevent damage to the drill press or the material.

6. What kind of maintenance is required for radial and oscillating drill presses?

Both radial and oscillating drill presses require regular maintenance to ensure proper operation and extend their lifespan. This includes cleaning and lubricating moving parts, checking for loose or damaged components, and sharpening or replacing drill bits as needed. Radial drill presses are more complex and may require more frequent maintenance than oscillating drill presses.

Final words:

Your unique demands and tastes determine the decision between a radial and an oscillating drill press. It is important to study and compare several types before making a purchase. You’ll be well-equipped to handle any drilling job that comes your way if you have the correct drill press in your workshop.

Your unique demands and tastes determine the decision between a radial and an oscillating drill press. It is important to study and compare several types before making a purchase. You’ll be well-equipped to handle any drilling job that comes your way if you have the correct drill press in your workshop.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023