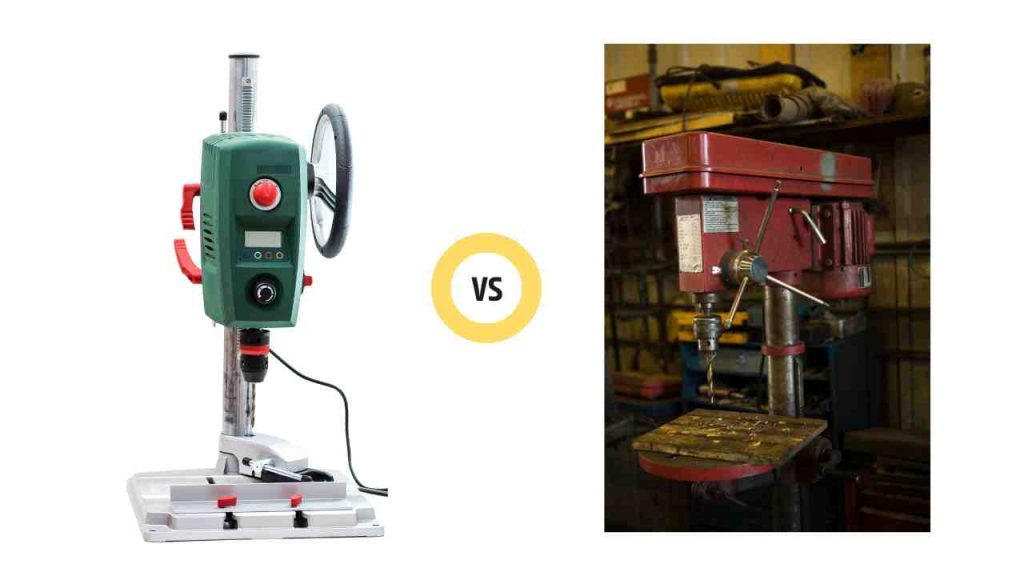

Are you looking to purchase a drill press but need help deciding which model to pick? Both standard and radial drill presses have distinctive characteristics and advantages. We’ll examine these two kinds of drill presses in more detail and contrast them in this blog article.

Our objective is to provide the information you need to pick the best tool for your needs. Whether a professional carpenter or a DIY enthusiast, having the appropriate drill press may make all the difference in how well your projects turn out. Grab a coffee and let’s explore the world of radial drill presses vs. Standard drill presses, shall we?

Comparison chart:

| Feature | Radial Drill Presses | Standard Drill Presses |

| Accuracy and Precision | High | Low |

| Stability | High | Low |

| Price | Expensive | Affordable |

| Size and Weight | Large and Heavy | Small and Light |

| Capacity | Limited | More Versatile |

| Angle of Drilling | Multiple Angles | Vertical Only |

| Ease of Use | Moderate | Simple |

| Speed Adjustment | Manual or Automatic | Manual |

| Dust Collection | Good | Poor |

| Versatility | Limited | More Versatile |

Rotary drill press:

A specific drill press with a rotating arm enables more accurate and adaptable drilling by positioning the drill bit at various angles.

Advantages:

1. Greater accuracy and precision: Because they can drill at multiple angles, radial drill presses are renowned for their high accuracy and precision. They are thus perfect for delicate work and drilling important holes.

2. Greater stability: The base of radial drill presses is more stable, which lowers vibrations and improves accuracy.

3. Ability to drill at various angles: Radial drill presses’ flexibility and accuracy are increased by their capacity to drill at multiple angles.

Advantages:

1. Greater accuracy and precision: Because they can drill at multiple angles, radial drill presses are renowned for their high accuracy and precision. They are thus perfect for delicate work and drilling important holes.

2. Greater stability: The base of radial drill presses is more stable, which lowers vibrations and improves accuracy.

3. Ability to drill at various angles: Radial drill presses’ flexibility and accuracy are increased by their capacity to drill at multiple angles.

Limitations:

Radial drill presses often have a limited drilling capacity, making them unsuitable for big or demanding tasks.

2. More costly: Radial drill presses often cost more thanstandard drill presses, making them unaffordable for anyone on a limited budget.

3. Radial drill presses are often bigger and heavier than standard drill presses, which may make them harder to store and move around.

Standard drill press:

An economical and user-friendly drill press that drills vertically.

Advantages:

1. More inexpensive: Compared to radial drill presses, standard drill presses are often more economical, making them a more viable alternative for those on a limited budget.

2. More adaptable: Standard drill presses can perform a larger variety of drilling jobs than radial drill presses, making them more adaptable.

3. Smaller and lighter: Compared to radial drill presses, standard drill presses are often lighter and smaller, which makes them simpler to store and transport.

Limitations:

1. Limited accuracy and precision: Because standard drill presses can only drill vertically, they tend to have less accuracy and precision than radial drill presses.

2. Less stable: Compared to radial drill presses, standard drill presses are less stable, which might lead to increased vibrations and poorer accuracy.

Similarities:

- Radial and standard drill presses are instruments for drilling holes in various materials, including wood, metal, plastic, and more.

- Both kinds of drill presses may handle a variety of drill bits, such as twist bits, spade bits, and Forstner bits, enabling you to complete a range of drilling operations.

- Both include speed adjustment choices: radial and standard drill presses often feature options for speed modification, enabling you to choose the ideal speed for your particular job and material.

- Both may be fixed to a workbench or stand, giving them a firm basis and facilitating operation. Drill presses of both kinds can be mounted to a workbench or stand.

- Both demand electrical power: Radial drill presses and standard drill presses require electricity to function, making them a practical and effective choice for drilling jobs.

Making the Best Tool Choice for Your Project:

1. Take into account your unique needs:

The sort of job you want to do with your drill press will primarily decide the kind of drill press you need. For instance, a radial drill press would be the better choice if you want to undertake delicate or accurate work, unlike a standard drill press, which might be ideal for more general drilling operations.

2. Budget: Your financial situation will also influence your choice. When choosing a drill press, it’s crucial to remember that radial drill presses are often more costly than regular drill presses.

2. Evaluate your work area:

1. Available space: Your drill press’s size and weight will affect both where you can keep it and how easily you can transport it. Consider the space available in your workshop or garage when selecting a drill press.

2. Accessibility: Think about where in your workstation your drill press will be accessible and how often you’ll use it. A smaller, lighter standard drill press could be more convenient to operate and carry about compared to a bigger, heavier radial drill press.

3. Ask experts or experienced users for help:

Last but not least, it is always a good idea to ask professionals or experienced users for assistance when making a choice. They can provide opinions and advice based on their own experiences, enabling you to make wise decisions.

By considering these things, you can choose the best tool for your unique requirements, guarantee that your drill press will live up to your expectations, and assist you in successfully finishing your tasks.

Frequently Asked Questions (FAQs)

1. Can I use a radial drill press for general drilling tasks like a standard drill press?

Yes, you can use a radial drill press for general drilling tasks. However, it is essential to remember that radial drill presses are more suitable for precise and delicate work due to their ability to drill at multiple angles. If your primary focus is general drilling, a standard drill press might be a more cost-effective option.

2. Are radial drill presses more difficult to operate than standard drill presses?

Radial drill presses can be slightly more challenging to operate due to their ability to drill at various angles and their typically larger size. However, with practice and proper guidance, you can quickly learn to use a radial drill press efficiently.

3. Can I use the same drill bits for both radial and standard drill presses?

Yes, you can use the same drill bits for both radial and standard drill presses. Both types of drill presses can handle various drill bits, such as twist bits, spade bits, and Forstner bits, allowing you to perform a range of drilling operations.

4. Is it possible to convert a standard drill press into a radial drill press?

While it is technically possible to modify a standard drill press to function like a radial drill press, it is generally not recommended. The modifications could compromise the stability and accuracy of the drill press, and it may be more cost-effective and safer to invest in a separate radial drill press.

5. Can I use a radial or standard drill press for woodworking and metalworking?

Yes, both radial and standard drill presses can be used for various materials, including wood, metal, plastic, and more. The key is to choose the appropriate drill bit and speed settings for the specific material you are working with.

6. How do I maintain my radial or standard drill press?

Proper maintenance of your drill press includes regular cleaning, lubricating moving parts, inspecting belts and pulleys for wear, and tightening any loose bolts or screws. Additionally, ensure that your drill bits are sharp and in good condition to maintain the efficiency and accuracy of your drill press.

Final Words:

The differences, benefits, drawbacks, and similarities between radial drill presses and standard drill presses were examined in this blog article. We stressed the value of considering your unique requirements, workspace, and budget when selecting the best project tool and urged consulting with experts or knowledgeable users.

The decision between a radial drill press and a standard drill press will ultimately be based on your unique demands and requirements. A radial drill press could be the better choice if you need great accuracy and precision, while a regular drill press might be better suited for drilling operations that require more general drilling. To choose the ideal for your tasks, consider your budget, workspace, and the work you will be undertaking.

Test both drill presses to see which suits you and your particular requirements the best. Making a more educated choice will be made possible by better grasping the benefits and drawbacks of each kind of drill press.

Your experiences with radial drill presses as opposed to standard drill presses would be much appreciated. Please leave any feedback or inquiries in the space provided below. Your opinions and suggestions will be helpful to others who may be selecting the best drill press for their tasks. I appreciate your reading.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023