Tools for clamping and holding are utilized in many different industries, including metalworking, woodworking, DIY projects, and many more. These instruments are necessary to keep the workpiece steady and secure while being worked on, which helps avoid accidents and mistakes during work.

Different clamping and holding equipment are needed for various jobs. For instance, a C-clamp is more suited for metalworking jobs than a bench vise is for woodworking projects. Choosing the right tool for the job is important to ensure that the task is done safely, quickly, and well.

Different clamping and holding equipment are needed for various jobs. For instance, a C-clamp is more suited for metalworking jobs than a bench vise is for woodworking projects. Choosing the right tool for the job is important to ensure that the task is done safely, quickly, and well.

Electing the appropriate tool for the task, the workpiece is held firmly and may be completed quickly and effectively. When an improper tool is used, it may lead to accidents, poor craftsmanship, and workpiece damage.

Comparison Chart:

| Feature | Clamp | Vise |

|---|---|---|

| Primary Purpose | Typically used for temporary holding or securing pieces during assembly or glue-up | Primarily used to hold a workpiece steady during operations like sawing, drilling, or finishing |

| Versatility | Highly versatile; can be used with a variety of materials and shapes | Less versatile; typically used with specific shapes and materials |

| Portability | Generally more portable, easier to store and carry | Generally less portable due to size and weight; often bolted to a workbench |

| Strength and Stability | Varies by type; some clamps can apply significant force but may not be as stable | Typically offer superior strength and stability, especially for heavy-duty work |

| Adjustability | Typically adjustable, with varying degrees of precision | Highly adjustable, often with a more precise control mechanism |

| Ease of Use | Usually easier and quicker to adjust, though this can vary by clamp type | Can be more complex to adjust, especially for fine precision work |

| Price | Usually less expensive, but price varies greatly by type and quality | Usually more expensive due to their heavy-duty construction and precision mechanisms |

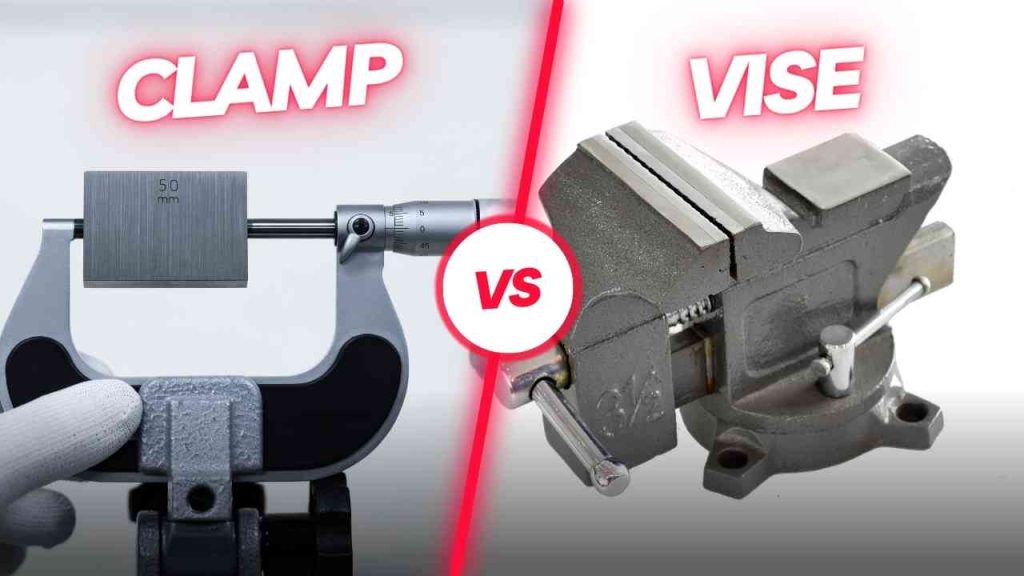

What are the differences between a clamp and a vise?

- Design: A clamp and a vise vary primarily in design. Typically, a clamp has a fixed jaw and a movable jaw that a screw or lever may change. In contrast, a vise has two jaws, one of which is permanent and the other movable by twisting a screw.

- Function: Function is another significant distinction between clamps and vises. Vises are used to keep things in a fixed position, while clamps are used to hold objects together. Vises are often used for drilling, cutting, and sanding, while clamps are generally used for gluing, clamping, and retaining materials together.

- Applications: While vises are often used in machine work, plumbing, welding, and building, clamps are frequently employed in these fields as well as in woodworking, metallurgy, and welding.

- Versatility: Clamps may be utilized for a greater variety of jobs and applications than vises, making them more flexible overall. They are useful tools to have on hand since they are also more portable. On the other hand, vises are more common in stationary locations like a workbench and, therefore, more specialized.

- Types: There are several types and designs of clamps and vises, each one suited to a particular use. Each kind has distinctive qualities. Therefore it’s critical to choose the appropriate instrument for the task.

What is a Clamp used for?

A clamp is a device that applies pressure on things to keep them firmly in place. There are many various sorts of clamps, and each has a unique design and purpose.

Clamp application areas include plumbing, construction, welding, metallurgy, and woodworking. They are used to clamp, glue, and keep items together. Additionally, they are used for fastening wood pieces together, a crucial step in many carpentry jobs. While welding, metal components are also held together using clamps. A decent collection of clamps is necessary for a workshop since they are flexible instruments for various tasks.

4 Types of Clamps:

- Bar Clamps: These lengthy clamps feature an adjustable and fixed jaw. Large, flat objects like doors and tables may be clamped with them.

- C-Clamps: These clamps feature a screw that tightens the jaws and are formed like the letter C. They are adaptable and may be used for several jobs, such as gripping wood while drilling or keeping metal components together when welding.

- Spring Clamps: These compact clamps are often employed for simple jobs like joining tiny pieces. They are easy to use and often used in crafts.

- Pipe Clamps: These clamps are made particularly to secure pipes. They are often used in plumbing and building projects.

What is a Vise used for?

An item may be held firmly in place while being worked on using a vise. Typically, it has two jaws, one fixed and can be changed by twisting a screw. The item being worked on may be fitted by adjusting the jaws, which can then be tightened to hold it firmly.

Vises are employed in many fields, including machine work, metallurgy, and carpentry. Choosing the proper vise for the task at hand is critical since there are several sorts of vises, each with a distinct function. The workpiece must be firmly positioned for the task to be done safely, accurately, and effectively. As a result, it is simpler to saw, drill, file, or mill an item when they are used to hold it firmly while being worked on. In machine shops, vises are also used to hold the workpiece firmly while machining.

4 Types of Vises:

- Bench Vise: This vise is attached to a workbench and used to hold items while being worked on. They come in various diameters and are used for various jobs, including drilling, sanding, and sawing.

- Pipe Vise: This vise is designed to keep pipes firmly in place. Plumbers, pipefitters, and other professionals who deal with pipes often utilize them.

- Drill Press Vise: A vise explicitly made for use with a drill press. It enables accurate drilling and can keep tiny items in place.

- Milling Vise: A milling machine commonly uses this kind of vise. It may hold tiny items firmly in place while machining precisely.

How can I decide between a clamp and a vise for a certain project?

- Identify the task: Before deciding between a vise and a clamp for a particular project, it is essential to determine the task. Think about the tools you’ll use, the task you’ll be performing, and the size and shape of the thing you’ll be holding.

- Consider the design of the vise or clamp: When selecting the best tool for the work, it’s crucial to consider the vise or clamp’s design. Vises normally have two jaws, one fixed and may be rotated to a different size. Contrarily, clamps feature a movable and a fixed jaw that can be changed using a screw or lever. The tool’s design will decide if it is appropriate for the job.

- Think about the function of the vise or clamp: The purpose of the vise or clamp is another crucial aspect to consider. Vises are used to keep things in a fixed position, while clamps are used to hold objects together. Vises are often used for drilling, cutting, and sanding, while clamps are generally used for gluing, clamping, and retaining materials together.

- Evaluate the vise or clamp type: Different vise and clamp kinds are made for various uses. To guarantee the work’s safety, effectiveness, and quality, it is crucial to choose the appropriate instrument for the task. For instance, a C-clamp is more suited for metalworking jobs than a bench vise is for woodworking projects.

- Consider portability: The tool’s portability is the last phase. Since they may be used for a larger variety of jobs and applications and are easier to move, clamps are often more portable than vises. On the other hand, vises are more common in stationary locations like a workbench and, therefore, more specialized.

Tips for properly and safely utilizing vises and clamps:

- Inspect for damage: Before utilizing a vise or clamp, look for cracks, corrosion, or other wear-and-tear. Use a replacement tool instead of a damaged one before continuing your task.

- Read the directions: Before using a vise or clamp, always read the directions. This will help you learn how to operate the item properly and prevent mistakes or mishaps.

- Modify the jaws: Change the vise or clamp’s jaws to suit the item you’ll be holding. Ensure the jaws are firmly closed, but not so tightly that they endanger the thing.

- Select the appropriate clamp or vice for the task: Select the appropriate clamp or vise for the task. Each tool has a distinct function, and employing the incorrect one might lead to subpar work, accidents, or workpiece damage.

- Use the right method: When using a vise or clamp, use the correct technique. This will guarantee that you receive the greatest outcomes while assisting you in preventing mishaps.

- Keep your workstation tidy: Keep your area clear of clutter and clean. A disorganized workstation might increase accident risk.

- Put on safety gear: When using a vise or clamp, wear gloves and safety glasses. If anything goes wrong, this will protect you from injury.

- Maintain good condition of your tools: Always maintain the excellent condition of your tools by cleaning, lubricating, and storing them appropriately.

Frequently Asked Questions (FAQs)

1. Can I use a clamp as a substitute for a vise or vice versa?

While clamps and vises have some similarities, they are designed for different purposes. Clamps are meant for holding objects together, while vises are designed to hold objects in a fixed position. It is essential to choose the appropriate tool for the task to ensure safety, efficiency, and quality of work.

2. Which type of clamp is best for woodworking projects?

Bar clamps are often the best choice for woodworking projects, as they have a long reach and can be used to clamp large, flat objects such as doors and tables. However, other types of clamps like C-clamps and spring clamps may also be useful in specific woodworking tasks.

3. What type of vise should I use for metalworking projects?

For metalworking projects, a bench vise or a milling vise is often the most appropriate choice. Bench vises are versatile and can be used for various tasks such as drilling, sanding, and sawing, while milling vises are designed specifically for use with milling machines.

4. How do I maintain my clamps and vises to ensure their longevity?

To maintain your clamps and vises, regularly inspect them for damage, clean them after use, lubricate any moving parts, and store them in a dry and safe location. Proper maintenance will help ensure the longevity and performance of your tools.

5. Can I use a pipe clamp for woodworking or other non-plumbing tasks?

While pipe clamps are designed specifically for securing pipes, they can be used for other tasks if necessary. However, it is essential to ensure that the pipe clamp is suitable for the task at hand and can provide the necessary clamping force and stability.

6. How do I know if I am using the right amount of clamping force?

The right amount of clamping force depends on the task and the materials being clamped. In general, you should apply enough force to hold the objects securely without causing damage. Over-tightening can lead to damage to the workpiece or the clamp itself, while under-tightening can cause the workpiece to shift or come apart during the task.

Final Words

Vises and clamps are necessary for holding and fastening items in position while working on them. It’s crucial to take the work at hand, the tool’s design and purpose, the kind of vise or clamp, and the mobility aspect into account when deciding between a vise and a clamp for a particular project.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023