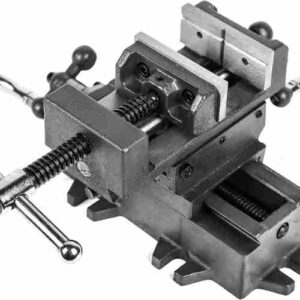

The foundation of every DIY or woodworking project is a bench vise. It acts as a dependable partner by holding your supplies in position while you perform your magic. With it, you’ll find it easier to maintain the stability of your materials, making it easier to cut, drill, sand, or do any other activity. Specific activity may become time-consuming and irritating as a result.

However, what happens if you don’t have access to one? Never worry; many solutions are available to assist you in easily completing your jobs.

What can I use if I don’t have a bench vise?

What can I use if I don’t have a bench vise?

- Clamps: These are multipurpose tools that may be found in various sizes and designs, including bar clamps, C-clamps, and spring clamps. For binding items together while you work on them, they are ideal.

- Vise grips: These include locking pliers and needle-nose pliers, may be used as an alternative to a bench vise and are available in several sizes and types.

- To keep items in place on a workbench, tiny, cylindrical devices called bench dogs might be installed.

- Homemade Bench Vise Alternatives: PVC pipes, wooden blocks, and bungee cords are just a few materials that may be used to create your own bench vise.

- Screwdrivers: In a hurry, you can clamp things in place using a screwdriver, giving you a fast and simple answer.

- Tapping blocks and hammers: These useful tools may be used to keep a piece of wood in place while you hammer nails into it. Materials may also be held in place with hammers by pounding on the opposing side.

- Bench hold-downs: These compact, movable tools may be fastened to a workbench to keep things in position precisely. They are ideal for those delicate minute tasks that require a steady hand.

- Bench stops: Mount these simple wooden or metal brackets to a workbench to keep things in place.

- Bench hooks: Install these simple wooden or metal brackets to a workbench to keep items in place.

- Workmate: With two jaws that can clamp items, this compact desk doubles as a vise. It’s ideal for those who want to work on projects while on the road or for those with a small workshop.

Safety Tips:

To ensure a safe and successful project, make sure to follow these tips:

- Wear safety glasses or goggles to shield your eyes from flying dust or debris.

- Wearing gloves will protect your hands from jagged edges and rough surfaces.

- Ensure your workpiece is firmly secured before beginning any job, such as cutting, drilling, or routing.

- Be cautious around your fingers and other body parts when working with power tools close to clamped materials.

- Never leave things that are clamped alone.

- Check the clamps’ tension often to ensure the materials are firmly in place.

- Ensure the hold-down clamp is properly set before using it to avoid crushing or harming the material.

- To prevent harming the workpiece, place the bench dog correctly—not too deeply or too shallowly.

- When using DIY bench vise substitutes, use care; ensure they are solid and secure before usage.

- To prevent harm, be cautious while using a screwdriver or hammer as a clamping tool near screws or nails.

Frequently Asked Questions (FAQs)

1. Can I use a bench vise for metalworking projects?

Yes, a bench vise can be used for metalworking projects. It can hold metal pieces securely while you cut, drill, or shape them. Ensure you choose a vise that is strong enough to handle the specific type of metal you are working with.

2. How do I choose the right bench vise for my needs?

When choosing a bench vise, consider factors such as the size of your workbench, the type of projects you will be working on, and the materials you will be using. Additionally, consider the jaw width, throat depth, and clamping force of the vise.

3. Can I use a bench vise for woodworking projects?

Yes, a bench vise can be used for woodworking projects. Ensure you choose a vise with wooden jaws or use soft jaw pads to prevent damage to the wood.

4. What is the difference between a bench vise and a portable vise?

A bench vise is a fixed tool that is mounted onto a workbench, while a portable vise is a smaller, more lightweight tool that can be moved around and clamped onto various surfaces.

5. Can I use a bench vise for plastic or other delicate materials?

Yes, you can use a bench vise for plastic or delicate materials, but make sure to use soft jaw pads or a vise with non-marring jaws to prevent damage to the material.

6. How do I maintain my bench vise?

Maintain your bench vise by regularly cleaning it, lubricating the moving parts, and checking for any loose or damaged components. Tighten any loose bolts and replace worn or damaged parts as needed.

7. Are there any safety precautions I should take when using a bench vise?

When using a bench vise, always wear safety glasses or goggles, use gloves to protect your hands, and ensure the workpiece is securely clamped before starting any work. Be cautious when working with power tools near clamped materials and never leave clamped items unattended.

Final Words

While a bench vise is a necessary piece of equipment for DIY and woodworking tasks, other substitutes may be used, including clamps, vise grips, bench dogs, Workmate, DIY alternatives, screwdrivers, tapping blocks, and hammers.

Considering that various projects could call for multiple tools or procedures, it’s crucial to remember that each of these other tools has its own characteristics and capabilities. Finding the best solution requires being resourceful and imaginative.

Regardless of whether you have a bench vise or not, you may function effectively and quickly by comprehending its significance and recognizing substitute equipment and techniques.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023