The drill press swing is vital to understand since it defines the greatest diameter of the workpiece that the machine can handle. This information is critical in determining the best job and workpiece size drill press.

Inadequate swing capacity in a drill press may prevent it from handling bigger workpieces, resulting in imprecise drilling, machine damage, and significant safety issues. On the other hand, a drill press with an excessive swing capacity may be more costly and cumbersome than required and may need to be more efficient for smaller workpieces.

Understanding the drill press swing and its importance in drilling activities may assist users in making educated choices when acquiring or utilizing a drill press.

What is Drill Press Swing?

What is Drill Press Swing?

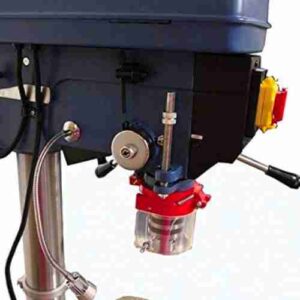

The swing of a drill press machine is the distance between the center of the Spindle (the spinning portion that holds the drill bit) and the column (the vertical support structure that supports the Spindle and motor).

It is effectively the greatest distance from the workpiece’s edge that can be drilled using a drill press. Swing capacity is often given in product specifications and is determined by the diameter of the biggest workpiece that can be drilled through the table’s center.

For example, a drill press with a swing capacity of 16 inches may accept workpieces up to 32 inches in diameter by drilling from both sides of the workpiece. Understanding a drill press’s swing capacity is critical for choosing the right equipment for the job and assuring the safety and precision of drilling operations.

Drill press swing measurement:

- The drill press swing is the distance between the Spindle’s center and the machine’s column. Use these methods to determine a drill press’s swing capacity:

- 1. Lower the table to its lowest position and secure it.

- 2. Put a straight edge or ruler against the drill press column, extending it over the Spindle’s center.

- 3. Measure the distance between the Spindle’s center and the straight edge or ruler. This distance reflects the drill press’s swing capability.

The significance of swing capacity:

- Allowing for varying workpiece sizes: A drill press’s swing capacity specifies the greatest diameter of the workpiece that can be drilled. Choosing a drill press with a swing capacity large enough to fit the workpiece size needed for the application is essential.

- Precision and accuracy: Drilling using a drill press with a suitable swing capacity may be precise and accurate. If the workpiece is too big for the drill press, it may shake or wobble during the drilling process, resulting in incorrect holes.

- Productivity and efficiency: Utilizing a drill press with a sufficient swing capacity may assist in boosting productivity and efficiency. It may eliminate the need for extra equipment or procedures to handle bigger workpieces and allow for multiple-hole drilling in a single configuration.

- Safety: Utilizing a drill press with an insufficient swing capacity for the workpiece might result in hazardous operating situations. It may cause the workpiece to become unstable, potentially resulting in risks like flying debris or workpiece breaking.

Drill Press Swing Influencing Factors:

- Spindle travel: The distance that the Spindle may move up and down inside the quill is referred to as spindle travel. The spindle travel of the drill press might impact its total swing capacity. The greater the spindle travel, the greater the depth that can be drilled into the workpiece. Nevertheless, since the distance from the center of the Spindle to the column is lowered, the swing capacity may be reduced.

- Quill diameter: The quill of a drill press is the portion that holds the Spindle and enables it to move up and down. The diameter of the quill may impact the drill press’s swing capacity. A wider quill diameter lets the Spindle move closer to the column without interfering with the workpiece, increasing swing capacity.

- Distance from spindle center to column: The distance from the spindle center to the column significantly affects the drill press’s swing capacity. The bigger the swing capability, the greater the distance. Nevertheless, increasing the distance might impact the drill press’s stability, particularly when drilling heavier workpieces.

- Drill press table size and movement: The drill press table supports the workpiece during drilling. The swing capacity of the drill press may be affected by the size and movement of the table. A greater table size may handle larger workpieces and boost the drill press’s swing capability. Moreover, a table that can be changed vertically or inclined allows drilling at varied angles, boosting the drill press’s adaptability.

Importance of Drill Press Swing:

- Drilling job flexibility: A drill press with a suitable swing capacity may offer to drill task flexibility. It can support various materials, sizes, and forms, providing more adaptability in drilling operations.

- Different workpiece sizes: A drill press’s swing capacity is critical for supporting diverse workpiece sizes. Utilizing a drill press with an insufficient swing capacity for the workpiece might result in incorrect drilling and associated safety issues.

- Precision and accuracy: Drilling operations may be performed with precision and accuracy using a drill press with an adequate swing capacity. It enables drilling straight, precise holes with little variation or wobbling.

- Productivity and efficiency: Utilizing a drill press with an adequate swing capacity may improve drilling efficiency and productivity. It enables numerous hole drilling in a single configuration, avoiding the need for extra equipment or procedures.

How do you choose the Best Drill Press Swing?

- Determine the kind of drilling tasks: Evaluate the materials, forms, and sizes of workpieces that will be drilled. This will aid in determining the machine’s required swing capacity.

- Match swing capacity to workpiece size: Choose a drill press with a swing capacity big enough to handle the maximum workpiece size that will be drilled. A drill press with a swing capacity at least twice the size of the biggest workpiece is suggested.

- Evaluate the following characteristics and specifications: Spindle speed, motor power, quill travel, table size and movement, and overall build quality are other characteristics and criteria to consider when purchasing a drill press. These elements may impact drilling operations’ efficiency, precision, and safety.

- Choose the right drill press: There are many kinds of drill presses available, including tabletop, floor-standing, and magnetic drill presses. While choosing the right sort of drill press, consider the machine’s size and weight and the available workspace.

- Look for user reviews and suggestions: Reading customer reviews and recommendations may give vital information about the drill press’s performance and dependability. Get input from users with comparable drilling requirements and applications.

What does 10 swing mean on a drill press?

The greatest distance from the center of the Spindle to the column on a drill press is 10 inches. To put it another way, 10 “Workpieces up to 20 inches in diameter may be accommodated by a swing drill press (measured from the center of the workpiece).

When choosing a drill press, the swing capacity is essential since it defines the maximum size of the workpiece that can be drilled using the machine. Choosing a drill press with a swing capacity at least twice the size of the biggest workpiece to be drilled is advised.

What is drill press swing distance?

The greatest distance between the center of the Spindle (the spinning portion that holds the drill bit) and the column (the vertical support structure that carries the Spindle and motor) of a drill press machine is referred to as the swing distance.

It is effectively the largest diameter of the workpiece that the machine can accept. Swing distance is often defined in product specifications and is determined by the diameter of the biggest workpiece that can be drilled in the table’s center.

For example, a drill press with a swing distance of 16 inches may handle workpieces up to 32 inches in diameter by drilling from both sides of the workpiece. Knowing a drill press’s swing distance is critical for choosing the right machine for the intended application and workpiece size and assuring the safety and precision of drilling operations.Bottom of Form

What is a spindle travel drill press?

The greatest depth that may be drilled into the workpiece is determined by spindle travel, which is an essential feature to consider when purchasing a drill press. Spindle travel refers to the greatest distance the Spindle may move up and down within the quill with a drill press.

The drill press’s quill is the portion that holds the Spindle and enables it to move up and down. The spindle travel is often indicated in the product specifications and might vary from a few inches to several inches depending on the drill press type.

A longer spindle travel enables deeper drilling in thicker materials. Knowing a drill press’s spindle travel is critical for choosing the right machine and workpiece size and guaranteeing the precision and accuracy of drilling operations.

Frequently Asked Questions (FAQs)

1. What is the relationship between drill press swing and workpiece size?

The drill press swing is directly related to the maximum workpiece size that the machine can handle. A larger swing capacity allows for larger workpieces to be drilled, while a smaller swing capacity limits the size of the workpiece that can be accommodated.

2. How do I measure the swing of my drill press?

To measure the swing of your drill press, lower the table to its lowest position and secure it. Place a straight edge or ruler against the column, extending it over the center of the Spindle. Measure the distance between the Spindle’s center and the straight edge or ruler. This distance represents the drill press’s swing capacity.

3. Can I drill larger workpieces with a smaller swing capacity drill press?

Attempting to drill larger workpieces with a drill press that has a smaller swing capacity can lead to imprecise drilling, machine damage, and safety issues. It is essential to choose a drill press with a swing capacity that can accommodate the workpiece size you intend to work with.

4. How do I choose the right drill press swing for my needs?

Consider the type of drilling tasks, workpiece sizes, and other features and specifications that are important for your projects. Choose a drill press with a swing capacity that is at least twice the size of the largest workpiece you plan to drill.

5. What factors can affect the drill press swing?

Factors that can influence the drill press swing include spindle travel, quill diameter, distance from the spindle center to the column, and table size and movement. These factors should be considered when selecting a drill press to ensure optimal performance and versatility.

6. Can I increase the swing capacity of my existing drill press?

It is generally not possible to increase the swing capacity of an existing drill press, as it is a fixed specification determined by the machine’s design and construction. If you need to work with larger workpieces, consider purchasing a drill press with a larger swing capacity.

Final Words:

Knowing the drill press swing is critical in choosing the right equipment and workpiece size. A drill press’s swing capacity specifies the largest diameter of the workpiece that the machine can handle, and selecting the proper swing capacity helps assure precision, efficiency, and safety in drilling operations.

Spindle travel, quill diameter, distance from the center of the Spindle to the column, and table size and movement are all factors that impact swing capacity. These characteristics might assist users in selecting the best drill press for their drilling requirements.

Selecting the suitable drill press swing entails defining the kind of drilling jobs, matching the swing capacity to the size of the workpiece, taking into account other features and specifications, selecting the appropriate type of drill press, and looking for user evaluations and suggestions. Users may get the best outcomes in their drilling operations by following these guidelines.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023