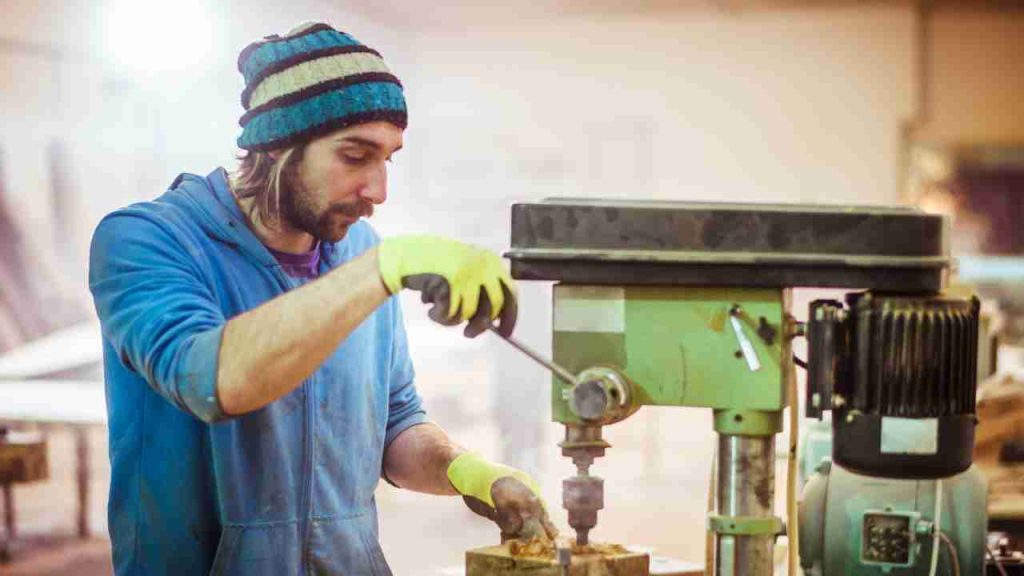

The drill press has become indispensable for countless craftsmen and engineers, from small-scale workshops to large-scale manufacturing facilities. Its accurate, efficient, and consistent drilling capabilities have revolutionized industries and changed how we make anything from furniture to complex equipment.

But have you ever considered when this incredibly useful machine was created? As we go back in time, let’s look at the beginnings of the drill press and how it evolved from primitive hand-powered equipment to the contemporary wonders we know today.

Whether you’re a seasoned professional or a curious hobbyist, learning about the drill press’s origins and evolution will give you a newfound appreciation for this remarkable piece of machinery. Now put on your safety goggles and prepare to be immersed in the intriguing history of the drill press!

The Evolution of Drilling: From Hand to Machine

The Evolution of Drilling: From Hand to Machine

1. Traditional hand drilling techniques

Our forefathers were already honing the art of drilling even before the creation of the drill press. Using their ingenuity and resourcefulness, they created basic yet effective hand-operated drilling tools to create holes in various materials.

i. Bow drills

Bow drills, although sluggish and labor-intensive, were a substantial advancement in drilling technology. The bow drill is one of the first known drilling tools, dating back to 2500 BCE. This basic

apparatus made out of a spindle, a bow, and a hearth, enabled users to generate friction and, eventually, holes in materials such as wood and bone. The bow would be rotated back and forth around the spindle, causing the spindle to revolve and drill into the material.

ii. Pump drills

Pump drills, which were widely utilized by ancient civilizations such as the Egyptians and Romans, exhibited mankind’s early skill in drilling. The pump drill emerged as a more efficient alternative to the bow drill as humans continued to innovate. Pump drills, operated by pressing down on a crossbar to rotate a spindle, employed a flywheel system to sustain momentum, making drilling quicker and more consistent.

2. Make the switch to mechanized drilling.

People started looking for more efficient drilling solutions over time, which led to the invention of the first mechanical drilling instruments.

i. Development of the brace

The brace emerged as a significant advancement in drilling technology around the 15th century. The hand-cranked drill brace had a U-shaped grip and a chuck to hold the drill bit. The user would place the bit against the material and rotate the brace to drive the bit into it. This method provided better control and torque, allowing to drill of larger, deeper holes.

ii. Emergence of the geared drill

The invention of the geared drill in the early nineteenth century marked yet another watershed moment in drilling history. Geared drills were far quicker and more efficient than their predecessors, laying the groundwork for the invention of the drill press.

These tools increased the user’s force using a gear and pinion system, offering even more drilling power and control. The eggbeater drill, for example, had a handle that moved gears, which subsequently revolved the drill bit.

When was the drill press invented?

When was the drill press invented?

1. The Industrial Revolution’s Role

The Industrial Revolution, which lasted from the mid-18th through the mid-19th centuries, resulted in enormous technical improvements and altered the industrial world. As the need for mass production and accuracy increased, sophisticated technology and tools were developed. The drill press was one such device that significantly influenced drilling efficiency and precision.

2. Invention of the drill press by James Nasmyth

i. Temporal period: 1830s-1840s

In the late 1830s to early 1840s, James Nasmyth, a Scottish inventor and engineer, is credited with developing the first drill press. His innovation was a reaction to the rising need in the industrial sector for more accurate and consistent drilling, especially for large-scale applications.

ii. Major characteristics of Nasmyth’s drill press

Nasmyth’s drill press, also known as a pillar drill, represented a significant advancement in drilling technology. It used a fixed, vertically aligned spindle and a worktable that could be changed to handle different material sizes instead of hand-operated tools.

The drill press, which used a system of gears and pulleys, enabled users to adjust the pace and power of the drilling operation, resulting in increased accuracy and efficiency. The drill press revolutionized drilling techniques and played an important role in shaping the manufacturing landscape during the Industrial Revolution.

The Drill Press in America:

1. American adoption of the drill press

When the Industrial Revolution moved over the Atlantic, American manufacturers realized the importance of the drill press. This revolutionary machine quickly gained popularity and became a cornerstone of American industry, playing a critical role in commodities production and economic progress. As demand for drill presses increased, so did the need for changes and enhancements to meet the specific needs of American businesses.

2. Innovations and improvements by American manufacturers

i. The patent of George Green

An American inventor, George Green, patented a substantial modification to the drill press design in 1861. His plan included a cam mechanism that allowed for quick and exact adjustment of the spindle’s depth, allowing the operator to control the drilling operation more precisely. This advancement significantly enhanced the functioning of the drill press and aided in its broad acceptance in the United States.

ii. Advances by Fosdick Machine Tool Company

The Fosdick Machine Tool Corporation also made significant contributions to the development of the American drill press. Founded in the late 1800s, the firm became a prominent producer of drill presses, introducing numerous significant inventions, notably the radial arm drill press. This novel design allows the spindle to travel horizontally along a radial arm, increasing drilling flexibility and variety.

Frequently Asked Questions (FAQs)

1. Who invented the drill press?

The drill press was invented by James Nasmyth, a Scottish inventor and engineer, in the late 1830s to early 1840s.

2. What was the purpose of the drill press invention?

The purpose of the drill press invention was to meet the increasing demand for more accurate and consistent drilling in the industrial sector, especially for large-scale applications.

3. How did the Industrial Revolution influence the development of the drill press?

The Industrial Revolution led to significant technological advancements and a shift towards mass production and precision. This created a need for more advanced tools, such as the drill press, which greatly improved drilling efficiency and accuracy.

4. What were some early hand-operated drilling tools?

Some early hand-operated drilling tools were the bow drill, which dates back to 2500 BCE, and the pump drill, which was widely used by ancient civilizations such as the Egyptians and Romans.

5. How did the drill press evolve in America?

In America, the drill press was adopted and improved by inventors and manufacturers like George Green and the Fosdick Machine Tool Company. Their innovations, such as the cam mechanism for spindle depth adjustment and the radial arm drill press, helped make the drill press more versatile and efficient.

6. What are some key features of Nasmyth’s drill press?

Nasmyth’s drill press, also known as a pillar drill, featured a fixed, vertically aligned spindle and an adjustable worktable. It used a system of gears and pulleys, allowing users to adjust the speed and power of the drilling operation for increased accuracy and efficiency.

Last words:

We’ve learned a lot about the drill press’s fascinating history, and it’s apparent that this powerful and adaptable equipment has gone a long way since its invention during the Industrial Revolution. From ancient civilizations’ rudimentary bow drills to the innovative designs of James Nasmyth, George Green, and the Fosdick Machine Tool Company, the drill press has evolved to meet the ever-changing needs of industry and craftsmanship.

The drill press is still used in workshops and industrial facilities across the United States and abroad. Its influence on the industrial industry is evident, as it has transformed how we produce and construct innumerable items.

As technology advances, the drill press will evolve alongside it, further pushing the boundaries of precision, efficiency, and innovation. Whether you’re a professional machinist or a do-it-yourself enthusiast, the next time you fire up your drill press, take a moment to appreciate the incredible history that has truly stood the test of time.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023