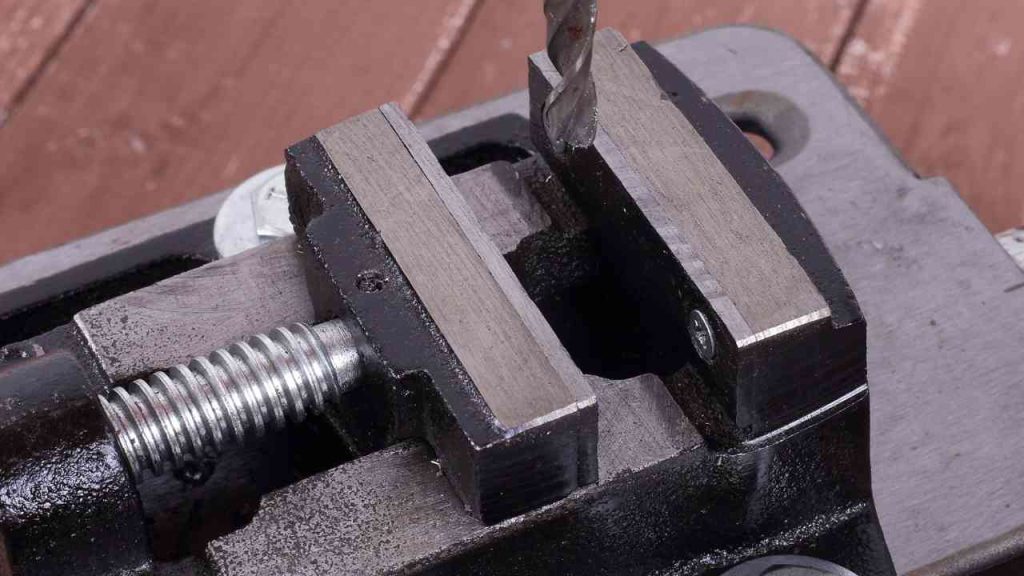

For every workshop, a drill press vise is an essential instrument. Drilling precise and accurate holes aid in holding workpieces firmly in position. A drill press vise must be correctly positioned on the drill press table to function.

Misaligned holes, more trouble setting the workpiece, and sometimes even damage to the drill press can all be caused by an inadequately centered vise. The significance of a correctly centered drill press vise will be covered in this blog article, along with instructions for obtaining and maintaining appropriate centering.

How to center a drill press vise properly?

How to center a drill press vise properly?

Step 1: Determine the center of the vise in step one. It would help if you first located the center of the vise to center it. You can take the vise’s dimensions and mark the midway of each side with a pencil. Connect the markers to form a crosshair after marking the midpoints. This will serve as the vise’s center.

Step 2: Establish the drill press table’s center. Identifying the drill press table’s center is the next step. To achieve this, measure the table’s length and breadth and mark the middle of each side, similar to how you did for the vise. Connect the markers to form a crosshair after marking the midpoints. The drill press table’s center will be here.

Step 3: Make the vise adjustments necessary to center it on the drill press table. The vise may be adjusted until it is centered on the drill press table after the centers of the vise and the table have been established. To do this, you must remove the mounting bolts from the vise and move it around until the vise’s crosshair lines up with the drill press table’s crosshair.

Step 4: Secure the vise by tightening it. You may tighten the mounting nuts to firmly anchor the vise once you’ve aligned it with the drill press table. To ensure that the vise is correctly aligned, ensure the bolts are tightened equally. Once the bolts are tightened, double-check the centering to make sure the vise hasn’t shifted.

Advice for keeping a vise centered:

- Regularly check the vise’s center and correct it as necessary: It’s a good idea to periodically check the vise’s centering to ensure it hasn’t gotten out of alignment. This is crucial if you use the vise regularly or if numerous persons utilize the drill press. Carry out the procedures mentioned above for finding the centers of the vise and drill press table to confirm the centering. Unscrew the mounting nuts and adjust the vise until it is centered if it is not.

- Use a locking mechanism to maintain the vise’s stability: The vise may be kept firmly in position and kept from shifting by using a locking device, such as a clamp or lock handle. This is particularly helpful if you adjust the vise regularly or handle hefty objects that might cause the vise to move.

- Don’t overload the vice: Overloading the vise may lead to misalignment or damage. Thus it’s crucial to avoid doing so. The manufacturer’s instructions for the maximum weight the vise can securely hold should always be followed. Consider utilizing extra supports or clamps to distribute the weight more evenly if you are working on a big project.

Frequently Asked Questions (FAQs)

1. Why is centering a drill press vise important?

Centering a drill press vise is crucial for accurate and precise drilling. A misaligned vise can lead to off-center holes, difficulty in positioning the workpiece, and potential damage to the drill press.

2. How often should I check the centering of my drill press vise?

It is recommended to check the centering of your drill press vise regularly, especially if the drill press is used frequently or by multiple people. This will help maintain accuracy and prevent misalignment issues.

3. Can I use a locking mechanism to keep my vise centered?

Yes, using a locking mechanism, such as a clamp or lock handle, can help maintain the stability of the vise and prevent it from shifting, ensuring that it remains centered.

4. What should I do if my vise is off-center?

If your vise is off-center, loosen the mounting bolts and adjust the vise until the crosshairs of the vise and the drill press table align. Tighten the mounting bolts evenly to secure the vise in place and double-check the centering to ensure it hasn’t shifted.

5. How can I prevent overloading my drill press vise?

To avoid overloading your drill press vise, always follow the manufacturer’s instructions for the maximum weight the vise can securely hold. If working on a large project, consider using additional supports or clamps to distribute the weight more evenly.

Final Word

Centering a drill press vise is a simple but essential step in guaranteeing precise drilling and effective work. It can take a little more upfront to center your vise correctly, but it will be worth it in the long run with more precise drilling and increased productivity.

Remember to value the value of having a correctly centered vise; it may significantly impact the outcome of your work. You may enhance your work’s quality and save time by adhering to the methods indicated in this blog article and keeping a correctly centered vise.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023