If you like woodworking or DIY projects, you may need to shape a piece of wood or metal into a circular form. This work is traditionally done on a lathe, but what if you don’t have one? You can use a drill press as a lathe with a few tweaks and the proper skill.

In this blog article, we’ll guide you through utilizing a drill press as a lathe, including safety considerations, setting up the workpiece, turning the workpiece, and completing the job. This article will help you obtain the round form you’re searching for with your beloved drill press, whether you’re a novice or an expert woodworker.

Why would you use a drill press as a lathe?

Why would you use a drill press as a lathe?

You may enhance your woodworking or DIY skills by utilizing a drill press as a lathe to execute jobs requiring turning without investing in extra equipment. Using a drill press as a lathe is a simple solution for individuals without room or funding for a separate lathe machine.

It’s also an excellent method to know if you need to turn a little piece of material but don’t want to buy a lathe. Another benefit of utilizing a drill press as a lathe is that it allows for more accurate turning due to its precision and speed control. A drill press can also operate with various materials, including wood and metal, making it useful equipment for your workshop.

Preparing the Drill Press:

It is essential to properly prepare a drill press before utilizing it as a lathe to guarantee safety and performance. The following are the stages for preparing the drill press:

- Clean the table and put the press away: Remove any clutter or trash from the drill press table to make room for your workpiece. To keep the drill press from shifting while in operation, secure it to a firm surface or stand.

- Install the essential components: A chuck or collet must be installed to hold the cutting tool to utilize a drill press as a lathe. Please read the manufacturer’s instructions for your drill press to see which parts you’ll need and how to assemble them.

- Change the drill press speed: The pace at which the workpiece spins is determined by the drill press speed. Adjust the speed to a suitable level for the material you’ll be dealing with. See the manufacturer’s instructions for your drill press to establish the appropriate speeds for various materials.

Putting the Workpiece Together:

Setting up the workpiece is critical when utilizing a drill press as a lathe. These are the stages to getting your workpiece ready:

- Choose the appropriate material and size: Select a material suitable for the job, such as wood or metal, and a size that will sit comfortably on the drill press table.

- Fasten the workpiece to the drill press: Clamps or a vise should be used to attach the workpiece to the drill press table. To prevent the workpiece from shifting during turning, ensure it is tightly and securely secured.

- Mark the center of the workpiece: Using a center finder or other measurement instrument, mark the center of the workpiece. This will assist you in aligning the workpiece with the cutting tool and achieving a symmetrical form.

Turning the Workpiece:

- After preparing your drill press to serve as a lathe, you may turn your workpiece. Following are the procedures for utilizing a drill press as a lathe to turn your workpiece:

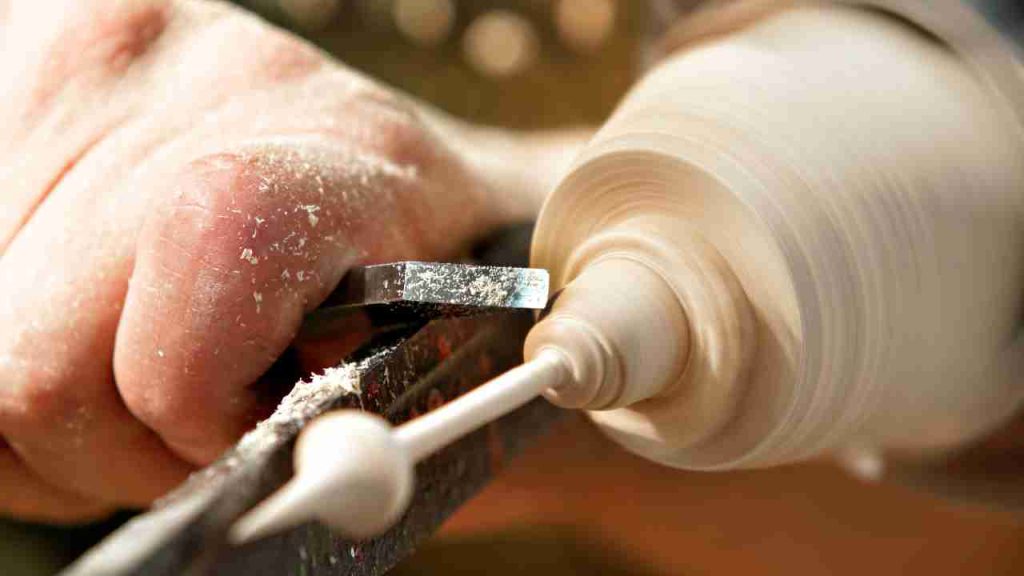

- Choose a cutting tool suited for the material you’ll be working with, such as a chisel or gouge for wood or a metal lathe tool for metal. Install the cutting tool in the drill press’s chuck or collet.

- Change the cutting tool height and angle: The form and depth of the cut are determined by the height and angle of the cutting tool. See the manufacturer’s instructions to find the right height and angle for your cutting tool. Adjust the tool height and angle depending on the form you want to produce and the material you’re working with.

- Turn the workpiece: Start the drill press and drop the cutting tool gently onto the workpiece. Use the quill feed handle to move the workpiece forward and produce the appropriate form. To minimize splintering or chipping the workpiece, avoid removing too much material at once and maintain the cutting tool sharp.

- Sand and polish the workpiece once you’ve obtained the correct form. This will smooth out any rough patches or tool marks. Depending on the material, sandpaper or a polishing wheel should be used.

Workpiece completion:

It’s time to finish your workpiece once you’ve turned it using a drill press as a lathe. These are the stages to completing your project:

- Sand and polish the workpiece: With progressively fine-grit sandpaper, sand it until it is smooth to the touch. A polishing wheel or compound may also provide a smooth, shining surface. If you’re dealing with wood, you may preserve the surface with a coat of wood finish or stain.

- Remove the workpiece from the drill press: Remove the workpiece from the chuck or collet and turn off the drill press. Tap lightly with a mallet or hammer if the workpiece becomes stuck.

- Examine the completed workpiece: After removing it from the drill press, check it carefully for defects or rough places. When required, sand or certain polish areas.

Suggestions and Techniques:

Here are some pointers to remember while utilizing a drill press as a lathe:

- Utilize a live center: A live center is a center that rotates with the workpiece and is positioned in the tailstock of a drill press. This may offer extra support and keep the workpiece from swaying or shaking during rotation.

- For various materials, use different cutting tools: Various materials need different cutting tools. To attain the greatest results, choose a cutting tool suited for the material you will be dealing with.

- Routine drill press maintenance, such as cleaning and lubricating moving components, may assist in assuring maximum performance and avoiding damage.

- Take regular breaks: Turning a workpiece may be an exhausting physical activity. Take regular rests to allow your arms to rest and prevent tiredness.

- If you’re new to turning, start with a tiny workpiece to develop a feel for the technique and prevent wasting material.

Precautions for safety:

Utilizing a drill press as a lathe may be a safe and efficient technique to turn a workpiece, but necessary safety procedures must be taken to prevent accidents or injury. These are some safety considerations to remember:

- Use PPE: Wear safety glasses or goggles to protect your eyes from flying debris and a dust mask to prevent breathing dust or debris.

- Secure the drill press: To prevent it from shifting while in operation, ensure it is firmly fastened to a sturdy surface or stand.

- Employ suitable clamping techniques: Securely attach the workpiece to the drill press table with clamps or a vice to prevent it from sliding during turning.

- Keep your hands and fingers away from the cutting tool: When using the drill press, keep your hands and fingers away from the cutting tool. To move the workpiece forward, use the quill feed handle.

- Avoid removing too much material at once: Cut in modest, steady increments to prevent removing too much material at once, which may cause the workpiece to vibrate or splinter.

- Sharpen the cutting tool: Employ a sharp cutting tool to avoid sliding or damaging the workpiece.

- Read and follow the instructions provided by the manufacturer: To guarantee correct usage and maintenance of your drill press and cutting tools, read the manufacturer’s instructions.

Frequently Asked Questions (FAQs)

1. Can any drill press be used as a lathe?

While not all drill presses are designed to be used as lathes, most can be adapted for this purpose with proper setup and precautions. It is essential to ensure your drill press has the necessary speed adjustments, attachments, and stability to handle turning tasks safely and effectively.

2. What are the limitations of using a drill press as a lathe?

Using a drill press as a lathe has some limitations compared to a dedicated lathe machine. These limitations include reduced turning capacity, less precise control, and a potentially slower work process. Additionally, a drill press may not be suitable for turning very large or heavy workpieces.

3. Can I use a drill press as a lathe for metalworking?

Yes, you can use a drill press as a lathe for metalworking, provided you have the appropriate cutting tools and speed settings for the specific metal you are working with. Ensure your drill press is securely fastened to a stable surface and follow all safety precautions when working with metal.

4. How do I choose the right cutting tool for using a drill press as a lathe?

The choice of cutting tool depends on the material you are working with and the desired shape of the finished workpiece. For wood, chisels or gouges are suitable, while for metal, you will need to use metal lathe tools. Always choose a sharp cutting tool and ensure it is securely fastened to the drill press.

5. What safety precautions should I take when using a drill press as a lathe?

Some key safety precautions when using a drill press as a lathe include wearing personal protective equipment (PPE) such as safety glasses and a dust mask, securing the drill press to a stable surface, using proper clamping techniques, keeping hands and fingers away from the cutting tool, and following the manufacturer’s instructions for your drill press and cutting tools.

Last words:

Finally, utilizing a drill press as a lathe may be a quick and efficient technique to turn a workpiece. You may obtain a circular form with precision and control by following the methods in this blog article, which include prepping the drill press, setting up the workpiece, rotating the workpiece, and completing the project.

You may also operate a drill press as a lathe safely if you take adequate safety measures, such as wearing personal protection equipment and fastening the workpiece to the drill press table.

Using a drill press as a lathe may help you finish jobs that need turning, whether a novice or an expert woodworker. So, give it a go and see what you can come up with!

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023