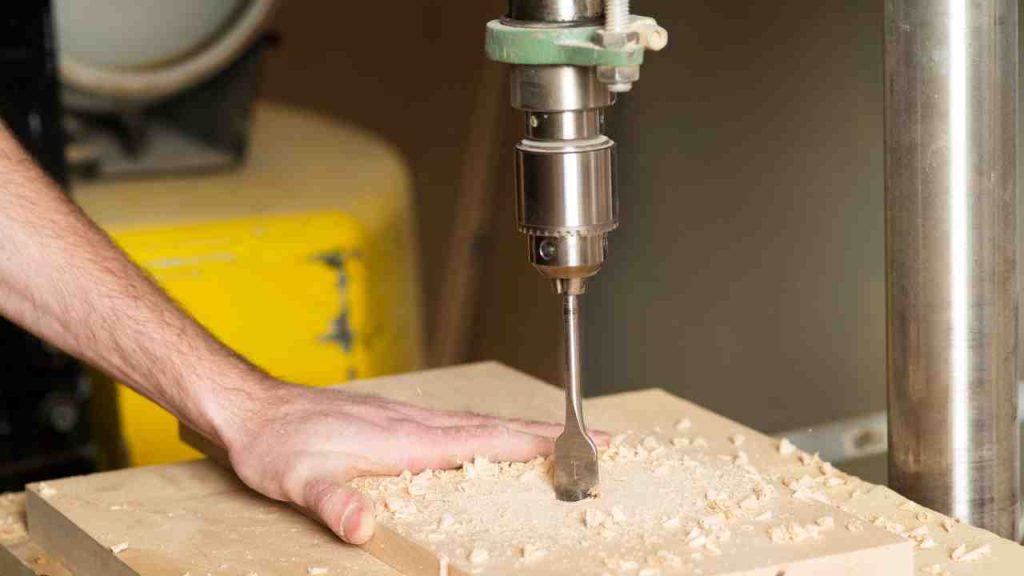

Drill presses are useful instruments that should be in every workshop or garage. These powerful devices let you drill accurate holes in wood, metal, and plastic. Understanding drill press height is critical for obtaining the best performance and safety, whether you’re a seasoned veteran or a newbie.

On the other hand, the height of your drill press is important in attaining precise and safe drilling. You may have back discomfort, weariness, or even damage if your drill press is too low or too high. In this blog article, we will examine the significance of drill press height and advise on determining the correct height for your drill press.

What is drill press height?

What is drill press height?

The height of a drill press is the vertical distance between the workpiece and the drill bit. To get precise and secure drilling results, it is crucial to adjust the drill press’s height depending on the size of the workpiece and the user’s height. While operating a drill press, height is important since it impacts drilling operations’ accuracy, safety, comfort, and efficiency.

Importance of Drill Press Height:

- Accuracy: The height of the drill press influences drilling accuracy. If the drill press is set too low, the drill bit may not be able to penetrate the workpiece completely. If the drill press is too high, the drill bit may wobble, causing the hole to be drilled incorrectly. You can drill precise, accurate holes every time if your drill press is set at the proper height.

- Safety: Operating at the incorrect drill press height might be dangerous. If the drill press is too low, you may have to bend over to reach it, which may cause back discomfort and weariness. This may also make it difficult to see what you’re drilling, putting you in danger of damage. If the drill press is too high, you may have to stand on tiptoes or a stool to reach it, which might lead you to lose your balance and collapse. This might cause significant harm, particularly if you’re using a drill press with a heavy workpiece.

- Comfort: Choosing the proper drill press height might make your job more pleasant. You may reduce undue pressure on your back, shoulders, and arms by positioning the drill press correctly. This allows you to work for extended periods without becoming exhausted or uncomfortable.

- Efficiency: Utilizing a drill press at the proper height will help you work more efficiently. When the drill press is set to the proper height, you may operate fast and correctly without adjusting your posture or stance. This may help you do your task faster and with better outcomes.

How to Determine the Right Drill Press Height?

- Measure the distance from the floor to your elbow to determine your optimal working height. This is your optimal working height or the height you can operate comfortably without stressing your back or arms.

- Measure the workpiece: Determine the height of the workpiece to be drilled. Add the material thickness to the appropriate working height you established in step 1. This will provide you with the correct height for your drill press for that specific workpiece.

- Change the table height: Most drill presses include an adjustable table that can be raised or lowered to fit varied workpiece heights. Adjust the table height to the appropriate height you estimated in step 2.

- Change the drill press head: Some drill presses have an adjustable head that can be adjusted up and down to fit varying workpiece heights. Set the drill press head so the drill bit is the same height as the workpiece’s top.

- Double-check the height: Double-check the drill press’s height before drilling to confirm that it is set to the right height for your workpiece. Make any final adjustments to the table or drill press head as needed.

Discussion of factors to consider, such as user height and the size of the workpiece:

There are various aspects to consider when establishing the proper height for a drill press, including user height and workpiece size.

User height: When establishing the optimal height for a drill press, the user’s height is an essential consideration. Taller users will need a taller drill press, whereas shorter people will require a lower one. Taller users may have to reach up and strain their shoulders or arms if the drill press is too high. Shorter users may have to bend over and strain their back if it is too low. You may work comfortably and effectively without strain or damage if the drill press is set to the correct height for the user.

Size of the workpiece: Another thing to consider when calculating the optimal height for a drill press is the size of the workpiece. If the workpiece is big or heavy, a taller drill press may be required to meet the workpiece’s height. A lower drill press may be more suited if the workpiece is tiny or lightweight. To guarantee precise and safe drilling, the drill press should be set so that the top of the workpiece is at the same height as the drill bit.

Additional elements to consider when establishing the appropriate drill press height include:

- The material being drilled.

- The size of the drill bit.

- The kind of drilling operation being done.

Drilling heavy metal, for example, may need a larger drill press than drilling thin wood.

Different types of drill press height adjustments:

There are two sorts of height changes to consider when altering the height of a drill press: manual and automated.

Manual Height Adjustment: Manual height adjustment is the most frequent method on a drill press. This form of adjustment requires the operator to physically raise or lower the drill press table to the correct height by loosening a locking mechanism. Although this change is simple and quick, precise adjustments may need more work and time.

Automated Height Adjustment: In some drill presses, automatic height adjustment is newer. A motor or hydraulic system automatically raises or lowers the drill press table to the required height. Automated height adjustment may save time, particularly for users who regularly alter the drill press’s height. These drill presses, however, are more costly and may need more maintenance than manually adjusted drill presses.

Digital readouts and laser guides, which may assist users in making more exact height changes and obtain accurate drilling results, may also be offered on certain drill presses.

6 Techniques for adjusting the height of the drill press:

- Measure the workpiece’s height: Before changing the drill press’s height, measure the workpiece’s height. To find the optimal height for the drill press for that specific workpiece, multiply the thickness of the material by the ideal working height (described before).

- Modify the drill press table: Most drill presses feature an adjustable table that can be raised or lowered to fit varying workpiece heights. Set the table height, so the workpiece’s top is at the same level as the drill bit.

- Adjust the drill press head: If required, adjust the drill press head to fit the workpiece height. Some drill presses include an adjustable head that may be adjusted up and down to fit the workpiece’s height.

- Employ a step stool or platform: If the drill press is too low to reach the appropriate height, elevate yourself to the proper height using a step stool or platform. Use a solid and secure platform capable of supporting your weight.

- Employ an adjustable vice: An adjustable vise may be used to hold the workpiece at the required height during drilling. This is particularly beneficial for drilling tiny or oddly shaped workpieces.

- Double-check the height: Double-check the drill press’s height before drilling to confirm that it is set to the right height for your workpiece. Adjust the table or drill press head to attain the correct height.

Common mistakes:

- Inaccurate drilling: Inaccurate drilling might occur if the drill press is too high or too low. If the drill press is set too high, the drill bit or the workpiece slide may wobble, resulting in an incorrectly drilled hole. If the drill press is set too low, the drill bit may be unable to completely enter the workpiece, resulting in a shallow or incomplete hole.

- Back discomfort and exhaustion: Using a drill press at an inconvenient angle might require the user to bend over, resulting in back pain and weariness. This might make it difficult to work for lengthy periods and can eventually lead to damage.

- Arm and shoulder strain: Utilizing an excessively high drill press might lead the user to reach up and strain their arms and shoulders. This may also make it difficult to work for lengthy periods and can eventually lead to damage.

- Unstable workpiece: If it is not properly positioned, it may become unstable while drilling, harming or damaging the workpiece.

- Inefficiency: Using a drill press at the incorrect height may diminish efficiency and lengthen the time it takes to accomplish a project. This might result in frustration and decreased productivity.

Frequently Asked Questions (FAQs)

1. How do I determine the ideal height for my drill press?

To determine the ideal height for your drill press, measure the distance from the floor to your elbow, which is your optimal working height. Then, measure the height of the workpiece and add it to the optimal working height. Adjust the drill press table or head to match the calculated height.

2. Why is the height of a drill press important?

The height of a drill press is important because it affects the accuracy, safety, comfort, and efficiency of your drilling operations. An incorrect height can cause inaccurate drilling, back pain, arm and shoulder strain, unstable workpieces, and reduced efficiency.

3. Can I adjust the height of my drill press table or head?

Yes, most drill presses have adjustable tables and some also have adjustable heads. You can raise or lower the table or head to accommodate different workpiece heights and user preferences.

4. What factors should I consider when setting the height of my drill press?

When setting the height of your drill press, consider the user’s height and the size of the workpiece. Other factors to consider include the material being drilled, the size of the drill bit, and the type of drilling operation being performed.

5. What are the common mistakes people make when setting the height of their drill press?

Common mistakes when setting the height of a drill press include inaccurate drilling due to incorrect height, back pain and fatigue from bending over, arm and shoulder strain from reaching up, unstable workpieces, and reduced efficiency.

6. How do I avoid these common mistakes when setting the height of my drill press?

To avoid these common mistakes, measure and adjust the height of your drill press according to your height and the size of the workpiece. Use the methods outlined in the article to calculate the optimal height and make adjustments using the manual or automated height adjustment mechanism. Double-check the height before drilling.

Final words:

The height of your drill press is critical to attaining precise, safe, and efficient drilling outcomes. By positioning your drill press correctly, you may operate comfortably and productively while producing precise and safe drilling results.

As a result, we urge readers to take action by measuring and adjusting the height of their drill presses for the best performance and safety. To establish the optimal height for your drill press, depending on your height and the size of the workpiece, use the methods outlined previously in this article. Change your drill press’s height using the manual or automated height adjustment mechanism, and double-check the height before drilling.

Recall that operating a drill press at the incorrect height may result in imprecise drilling, back discomfort, arm, and shoulder strain, an unsteady workpiece, and decreased efficiency. Don’t allow these typical blunders to compromise your drilling performance or safety.

Take the time to measure and adjust the height of your drill press, and you’ll be able to operate confidently, knowing that you’re getting precise, safe, and efficient drilling results.

- Where are WEN drill presses made? - April 2, 2023

- Where are Rikon drill presses made? - April 1, 2023

- Where are Powermatic drill presses made? - April 1, 2023